If you're buying a tractor that vibrates at what you say is the optimal range, then you're buying the wrong tractor. Any good operator will listen for noise and feel for vibration and won't run a tractor under those conditions. But again proper maintenance is much more important than trying to out-engineer the engineers that built the tractor.

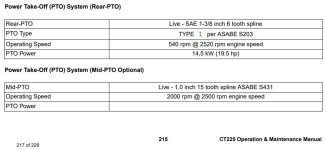

Attachments and tractors are built to run at that speed.

As long as you've given the motor a proper warm up before running at full "optimal" speed and also given it a proper cool down before shutting it off, you will not extend the life of the motor appreciably by running it at a lower RPM.

Run it the way it was designed, if there is any noise or vibration then you need to investigate further.

And IF you have any noise or vibration please let us know here on TBN and keep us informed on how your dealer responds to help others make somewhat informed decisions on which tractor to buy.

Forums like TBN should encourage manufacturers to build a better product.