k0ua

Epic Contributor

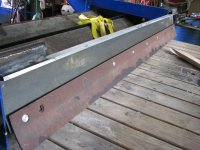

You mentioned cutting sheet steel. While many methods will work, I like to use my Bosch jigsaw with a metal cutting blade, especially if you need to cut any kind of curves in the steel. The advantages are fairly quick cut (on sheet steel), and not much heat, no sparks, fairly low noise, easy to control and stay on the cut line. Also cheap to operate compared to other methods. Now as you go into thicker steels, you will need to look at another method (torch, plasma) as the jigsaw will just be too slow.