Hello from s.e. Oklahoma, the Kiamichi Mtns. area and the rocky ridge I try to grow grass on. I am glad to find this forum, which I found while looking for help in diagnosing an increasing screeching/whirring noise that I interpret to be from a pulley, sheave or PTO clutch, in the front area of my 2002 GX335. The tractor has about 750 hrs. on it. The noise has been present for about the last 40 hrs or so at a low to moderate volume, but made a quantum leap in volume a few days ago. The PTO clutch was replaced a few years ago, and as best I can recall, the sound then was similar. I see that there are many threads and videos on the 'net about replacing the drive belt, but only a few on replacing the main drive pulley (if that is the problem). I have read some of the posts with pics on replacing the drive belt, with either removing the rear and mid body sections, and with not removing the body parts. Those are helpful but more suggestions/tips on removing the PTO clutch and main drive pulley, if that is what it turns out is needed, would be even more helpful. Any ideas on diagnosing what is making the noise would be appreciated. It now seems to vary some in volume since it got louder, as if whatever is causing the noise is varying in intensity. Switching the PTO on/off doesn't seem to make any difference, the noise is present sitting at idle (where the noise level variance is more detectable) and running full blast with or without blades engaged. There doesn't seem to have any effect on the trans or mobility of the tractor. Thanks for your input. Joe

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Diagnose"pulley" noise; R&R main pulley?

- Thread starter Moe Rocks

- Start date

- Views: 29018

More options

Who Replied?

/ Diagnose"pulley" noise; R&R main pulley?

#1

Al 2

Gold Member

You may be able to determine a bad bearing using a stethoscope. Look here: Garage Essentials 2 - Mechanics Stethoscopes (diagnose bad injectors, bearings, ect...) - YouTube and search Youtube for more options.

Al

Al

Richard001

Veteran Member

Moe,

Welcome to TBN.

So if I understand correctly, the noise you hear is there with the PTO off as well with the PTO on. Normally if you hear a lot of noise with the PTO engaged, i.e. the deck is operating, one would suspect worn bearings on the idler pulleys.

But if you are having a lot of noise with just the engine running, then there is some issue with the engine itself or with the hydrostatic drive. Remember the hydrostatic drive runs all the time that the engine is running. Check for a worn idler on the hydrostatic drive belt.

Richard

Welcome to TBN.

So if I understand correctly, the noise you hear is there with the PTO off as well with the PTO on. Normally if you hear a lot of noise with the PTO engaged, i.e. the deck is operating, one would suspect worn bearings on the idler pulleys.

But if you are having a lot of noise with just the engine running, then there is some issue with the engine itself or with the hydrostatic drive. Remember the hydrostatic drive runs all the time that the engine is running. Check for a worn idler on the hydrostatic drive belt.

Richard

Moe,

"But if you are having a lot of noise with just the engine running, then there is some issue with the engine itself or with the hydrostatic drive. Remember the hydrostatic drive runs all the time that the engine is running. Check for a worn idler on the hydrostatic drive belt."

Thanks Al and Richard for the comments. In my first attempt to listen closely to the noise, as far as I care to get under the tractor with it running and on the ground, it does sound about equal listening near the rear and near PTO/main drive pulley - cannot tell any difference that way. The short video on stethoscope use is good. There are of course many others on the same subject, this is one I thought was a really good explanation: How to diagnose a whining noise in your accessory drive - YouTube . I had thought about using a stethoscope since I have medical stethoscopes but had not thought about using a shop type with the long probe, or just a screwdriver. So I will try a scope with a probe on the PTO bolt and as close as I can safely get to the hydro pulley, as well as the idlers. To really check the hydro pulley well with a stethoscope would seem to require pulling at least the rear body section off. Since replacing any of the pulleys would at least be easier by removing the rear and mid body sections in order to make R&R of the belt easier, I will do that first. Then with a stethoscope or screwdriver try to determine where the problem is and buy parts accordingly. If the culprit is either the main drive pulley or the hydro pulley I will probably replace all of the idlers anyway, to hopefully prevent having to pull the body parts again. I may even replace both the drive pulley and hydro pulley as preventive maintenance, and because of a few years of strain on the bottom crank end in mowing the tall tough grass mentioned below. I have not looked at prices for the hydro pulley, but the main drive pulley and idler prices don't seem too bad on e-bay, etc.

One of my main concerns still is the job of pulling off the main drive pulley. Specifically - getting the pulley off without putting undue strain or pressure on the crank end, maybe causing seal damage or even bearing damage. I once had a leaking bottom seal on the crank. The dealership owner said it was likely due to putting too much strain on the bottom of the crank, and thereby on the seal, by mowing too fast through tall and tough grasses. I used to let some of the dalisgrass at the back of my lot get 25-30" high before mowing. That stuff is really tough anyway, so going through it fast is evidently more than what the Deere engineers had in mind for the lower crank seal and bearing. That is the source of my concern about how to remove the pulley without damaging that bottom seal by prying or uneven pressure. Any pointers on that are still welcome.

Thanks again, Joe (PS - couldn't figure out how to reply without doing the quote. Maybe I'm missing something, but am ok with doing the quote anyway)

Spanner

Veteran Member

Hi Moe. How did you fare?

Any noise is a bad noise.

On the GX series the Trans Belt is rotating all the time the engine is. So most likely one of your 3 x idlers is failing.

If the noise goes away (I know you say yours is constant but for anybody who finds this thread in a 'Search') if the noise goes away when PTO is engaged the bearing failing is the one at the bottom of the PTO clutch.

For completeness please report your result of the repair.

Any noise is a bad noise.

On the GX series the Trans Belt is rotating all the time the engine is. So most likely one of your 3 x idlers is failing.

If the noise goes away (I know you say yours is constant but for anybody who finds this thread in a 'Search') if the noise goes away when PTO is engaged the bearing failing is the one at the bottom of the PTO clutch.

For completeness please report your result of the repair.

Hi Moe. How did you fare?

Any noise is a bad noise.

On the GX series the Trans Belt is rotating all the time the engine is. So most likely one of your 3 x idlers is failing.

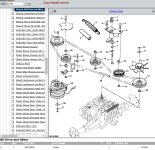

View attachment 514424

If the noise goes away (I know you say yours is constant but for anybody who finds this thread in a 'Search') if the noise goes away when PTO is engaged the bearing failing is the one at the bottom of the PTO clutch.

For completeness please report your result of the repair.

Spanner, no repair has yet been done. After my initial post I decided to call the local JD dealer and try to get an idea of what they may charge for a replacement of any of the main drive pulleys.They had about 50+ units in line at the time so I was going to call back a few days later. I didn't want to take on a project that I was so unsure of about how long it might take me, what hang-ups may occur, etc. We were/are dealing with repairs to house and 3 buildings from major hail damage, and a daughters' wedding coming up, so I decided to go ahead and mow with the tractor as-is. I mowed and acre or so, and the noise didn't seem as bad what it had been when there was some variance in it. That variance caused me to wonder if there was just some junk jammed in somewhere. The noise is still there, both with pto off and on, though louder with it on. My best description of it now would be somewhat like a siren, rather high-pitched. After about 2 hrs it didn't sound any worse. I removed the deck to clean it and put on some graphite paint and noticed that the drive belt was chunked in a few places, only on one of the two parts at any one spot, of the areas I looked at. The only other thing I have done is get some easy-to-use ear/hearing protection, realizing that the louder, higher pitched noise was probably going to damage my hearing. In another month the grass/weed growth rate should slow, if the usual takes place, and I may just take it to the dealer then. Meanwhile, the noise level and quality seems to be about the same as a few months ago, so I will continue to mow as-is and hope it will not worsen or crater anytime soon. I am still interested in fixing it myself, because the last time I had the dealer do something with it I think they hit me with what I thought was an exorbitant amount of labor for what the problem was. My main concern about doing the fix myself is still about how to remove the pulley from the crank (if that is what the pulley is directly mounted on) without doing any damage to the seal or bearing. Info on that would still be appreciated. When I do get the problem resolved I will report back, though it will be at least a month or so, and maybe not until this fall. Thanks for the comments Spanner.

beenthere

Super Star Member

- Joined

- Aug 16, 2001

- Messages

- 18,612

- Location

- Southern Wisconsin, USA

- Tractor

- JD_4x2_Gator, JD_4300, JD_425, JD_455 AWS, added JD_455, JD_110, JD_X485(sold)

Moe

You can go to jdparts

John Deere - Parts Catalog

and see schematics of the parts by putting in the model #, then browsing the alphabetic listing. Here may be a shot of your parts.

You can go to jdparts

John Deere - Parts Catalog

and see schematics of the parts by putting in the model #, then browsing the alphabetic listing. Here may be a shot of your parts.

Attachments

Spanner

Veteran Member

Well Moe, You're not doing the drive system any favours by continuing to run with a damaged belt.

Changing belt requires:

Deck off.

Release big covered spring tensioner (# in my and Beenthere's pix above)

Remove PTO Clutch - Disconnect wiring at plug. Remove centre bolt. Unit should come off with 'gentle persuasion'.

Pulley above should drop down similarly.

Couple of wire-guides on the belt to loosen and allow belt removal also.

Idler bolts are of the Square Shank type which will stay put as you undo nuts to remove idlers.

Note PTO Clutch has an Anti-rotation 'Peg' located in one corner. Ensure you refit in correct orientation.

Strongly advise against continuing to opertate with a damaged belt. Causes excess wear on tensioner plate etc.

Regards,

:wrench:

Changing belt requires:

Deck off.

Release big covered spring tensioner (# in my and Beenthere's pix above)

Remove PTO Clutch - Disconnect wiring at plug. Remove centre bolt. Unit should come off with 'gentle persuasion'.

Pulley above should drop down similarly.

Couple of wire-guides on the belt to loosen and allow belt removal also.

Idler bolts are of the Square Shank type which will stay put as you undo nuts to remove idlers.

Note PTO Clutch has an Anti-rotation 'Peg' located in one corner. Ensure you refit in correct orientation.

Strongly advise against continuing to opertate with a damaged belt. Causes excess wear on tensioner plate etc.

Regards,

:wrench:

Spanner, thank you, very much, for the straight-forward practical info. Will certainly take you up on the advice, ASAP. Unfortunately for the tensioner plate, etc., I will need to mow again in the next few days before doing the R&R of necessary parts. Daughter's wedding is next Saturday, and of coursed I am over my ears in things to do - e.g., repairing both indoor and outdoor furniture, other lawn care, ad infinitum. I may just do the "lawn" around the house (~ 1.0 acre) and let the rest go until I can do the repairs - although have been letting the other go for several weeks anyway - we have had a deluge of rain, and with everything else, have not mowed the non-lawn, which is already pretty thick - but has been worse. It will be at least 10 days or so before I can get to the repairs. Then, I probably will wait until I get it apart before ordering parts or buying them locally, but will report back when done. Might be asking for more on-line adult supervision too! Thanks again, Joe

Spanner

Veteran Member

Spanner, thank you, very much, for the straight-forward practical info. Will certainly take you up on the advice, ASAP. Unfortunately for the tensioner plate, etc., I will need to mow again in the next few days before doing the R&R of necessary parts. Daughter's wedding is next Saturday, and of coursed I am over my ears in things to do - e.g., repairing both indoor and outdoor furniture, other lawn care, ad infinitum. I may just do the "lawn" around the house (~ 1.0 acre) and let the rest go until I can do the repairs - although have been letting the other go for several weeks anyway - we have had a deluge of rain, and with everything else, have not mowed the non-lawn, which is already pretty thick - but has been worse. It will be at least 10 days or so before I can get to the repairs. Then, I probably will wait until I get it apart before ordering parts or buying them locally, but will report back when done. Might be asking for more on-line adult supervision too! Thanks again, Joe

Ok, Your call...

Anyway-

Stop typing. Start working!

Best wishes to the bride & groom.

:wrench:

So relatively speaking how much damage would be done if I replaced the belt, mowed for about 1.5-2.0 hrs., then replaced the pulley(s) in a couple of weeks? Or, would it be a great waste of time to get to the point of replacing the belt and not replace the pulley(s) and whatever else is needed?

(Would rather be mowing than typing, even wrenching than typing - have the tools, but am not a "mechanic"). Thanks.

(Would rather be mowing than typing, even wrenching than typing - have the tools, but am not a "mechanic"). Thanks.

Another pertinent Q., Spanner: how much time would you est. to do the job of replacing the main drive pulley and one idler, for an amateur mech. who has never done that particular job? And, just to be clear, from what you said above, a pulley puller is not usually necessary, is that right?

Spanner

Veteran Member

So relatively speaking how much damage would be done if I replaced the belt, mowed for about 1.5-2.0 hrs., then replaced the pulley(s) in a couple of weeks? Or, would it be a great waste of time to get to the point of replacing the belt and not replace the pulley(s) and whatever else is needed?

(Would rather be mowing than typing, even wrenching than typing - have the tools, but am not a "mechanic"). Thanks.

You have to drop (release/loosen/remove) the idler pulleys in order to replace the belt. In my world I think "The pulleys have done as much work as the belt has. The belt has failed. It's a combo job now..."

Replacing the pulleys takes no more time than refitting the 'old/'worn'/used/ 'about-to-fail-who-knows-when' pulleys.

Remember (AND THIS IS IMPORTANT TO ALL WHO BOTHER TO READ MY POSTS) the new idler pulleys carry a 3-month "Parts Warranty" from JD, irregardless of who fits them. Keep the old ones as 'spares' but rest assured you have not wasted your money and will not be wasting your time. Time is money.

Another pertinent Q., Spanner: how much time would you est. to do the job of replacing the main drive pulley and one idler, for an amateur mech. who has never done that particular job? And, just to be clear, from what you said above, a pulley puller is not usually necessary, is that right?

Puller not usually necessary - Correct, Moe.

As for collateral damage. Unnecessary vibration (worn belt or flat-spotted idlers) will impact on both the Crankshaft Bearing, PTO Clutch Bearings and the Gearbox Input Shaft Bearing.

As I said, "Your call".

To remove mower deck, dismantle drive belt, steering & idlers. Fit new belt and as many idlers as you need (ideally all three) and reassemble takes me one (1) Hour. But that is going hard-out to save customers time=money.

For the amateur/homeowner it could be a half-day job and that's not a bad thing. Every minute under your GX is a learning minute and not time wasted. I recommend a Parts diagram (See earlier posts), a clean working space, supportive partner with cold/hot drinks and no interruptions.

Even if it takes you all day. Who cares? It's your mower and your own time.

Look around under there. Have an oil can handy and drop a blob of oil where you think a wearing part might rub.

You will be amazed with the reduction in the noise level.

:wrench:

Egon

Epic Contributor

Have you tried to wiggle the pulleys? Is the belt tensioned?

Quick fix for a loose belt may be some belt dressing.

Quick fix for a loose belt may be some belt dressing.

Spanner

Veteran Member

Respectfully to Egon:

This is a spring-tensioned v-belt drive.

"Belt Dressing":

Belt Dressing is a panacea.

"Panacea"

noun

1. a remedy for all ills; cure-all.

2. a solution for all difficulties.

In my opinion there is no place for 'Belt Dressing' in todays V-Belt Power-Train world. :twocents:

Look for reasons why the v-belt isn't tensioning correctly. Tensioner plate pivot may be binding?

:wrench:

This is a spring-tensioned v-belt drive.

"Belt Dressing":

Belt Dressing is a panacea.

"Panacea"

noun

1. a remedy for all ills; cure-all.

2. a solution for all difficulties.

In my opinion there is no place for 'Belt Dressing' in todays V-Belt Power-Train world. :twocents:

Look for reasons why the v-belt isn't tensioning correctly. Tensioner plate pivot may be binding?

:wrench:

Egon

Epic Contributor

I did look it up.

V belts may wear pulleys. With the wear on pulleys\belts and belt stretch the tensioner may not have enough travel to function properly.

Belt dressing has seen use on many multiple V belt drives of considerable hp. in industrial settings.

V belts may wear pulleys. With the wear on pulleys\belts and belt stretch the tensioner may not have enough travel to function properly.

Belt dressing has seen use on many multiple V belt drives of considerable hp. in industrial settings.

"Replacing the pulleys takes no more time than refitting the 'old/'worn'/used/ 'about-to-fail-who-knows-when' pulleys."

Spanner, other than an apparent slight misunderstanding of my statement about replacing just the belt, all you said is understood, agreed with and well received on my part. My statement about replacing the belt only referred to putting on a new belt, not refitting old pulleys that may give out any moment. Maybe I don't fully understand all that is entailed in replacing the belt, such as if it is necessary to remove one or more pulleys to replace the belt? At any rate, I am not one that would go to the trouble of a few hours labor/time and not replace questionable parts such as worn pulleys with new ones. I've looked at all the pulley prices (have the parts diagrams already in Favorites) and they seem to me to be some of the more reasonably priced JD items, well worth replacing while having access to them.

I have the clean, A/C'd shop with cold drinks in the 'fridge, the tools - other than a puller which I could borrow from O'Reilly's if necessary. Spouse leans more toward taking it to the dealer so I can use my time on other things, but will likely accept me doing the work, after this partial solution: I have a guy coming this Wed. to mow for me. I've done the edging & weed/whacking, so is not to big a deal for him. After daughter's wedding I will tackle the repairs and let you know how it turns out.

Other than maybe having unforeseen difficulty with one thing or another, I do look forward to the maintenance and cleaning opportunity. This winter while cleaning and painting the underside of the deck I pressure washed and cleaned a lot of mud from around and on the trans, as best I could with the rear body on. I also installed a new high-back seat with arm rests. - I like having things as ship-shape as I reasonably can, so will like being able to clean and check things out with the rear body off.

Thanks to both Spanner and EGon for the useful tips. Egon may be right about belt dressing being useful in some cases, but with properly working parts and new belt, it seems that should not be necessary, though it does bring a Q. to my mind if a belt dressing might possibly be a useful preventive maintenance item? (There may have been some belt slippage involved due to a pulley that wasn't turning as freely as it should. A couple of times I did notice some burning smell, but only briefly, another reason I thought for a while that the noise might just be due to a twig or something caught in a pulley.)

(There may have been some belt slippage involved due to a pulley that wasn't turning as freely as it should. A couple of times I did notice some burning smell, but only briefly, another reason I thought for a while that the noise might just be due to a twig or something caught in a pulley.)

One other Question, and I'll sign off for now: the tractor has about 760 hours. I think in the owners manual JD claims the entire mower should be good for about 2,000 hrs. with good maintenance - which has been done, as far as items on the JD maintenance schedule, plus repairs. I wonder how common it is for any of the pulleys to be failing at that many hours, or less? Thanks to all.

Spanner, other than an apparent slight misunderstanding of my statement about replacing just the belt, all you said is understood, agreed with and well received on my part. My statement about replacing the belt only referred to putting on a new belt, not refitting old pulleys that may give out any moment. Maybe I don't fully understand all that is entailed in replacing the belt, such as if it is necessary to remove one or more pulleys to replace the belt? At any rate, I am not one that would go to the trouble of a few hours labor/time and not replace questionable parts such as worn pulleys with new ones. I've looked at all the pulley prices (have the parts diagrams already in Favorites) and they seem to me to be some of the more reasonably priced JD items, well worth replacing while having access to them.

I have the clean, A/C'd shop with cold drinks in the 'fridge, the tools - other than a puller which I could borrow from O'Reilly's if necessary. Spouse leans more toward taking it to the dealer so I can use my time on other things, but will likely accept me doing the work, after this partial solution: I have a guy coming this Wed. to mow for me. I've done the edging & weed/whacking, so is not to big a deal for him. After daughter's wedding I will tackle the repairs and let you know how it turns out.

Other than maybe having unforeseen difficulty with one thing or another, I do look forward to the maintenance and cleaning opportunity. This winter while cleaning and painting the underside of the deck I pressure washed and cleaned a lot of mud from around and on the trans, as best I could with the rear body on. I also installed a new high-back seat with arm rests. - I like having things as ship-shape as I reasonably can, so will like being able to clean and check things out with the rear body off.

Thanks to both Spanner and EGon for the useful tips. Egon may be right about belt dressing being useful in some cases, but with properly working parts and new belt, it seems that should not be necessary, though it does bring a Q. to my mind if a belt dressing might possibly be a useful preventive maintenance item?

One other Question, and I'll sign off for now: the tractor has about 760 hours. I think in the owners manual JD claims the entire mower should be good for about 2,000 hrs. with good maintenance - which has been done, as far as items on the JD maintenance schedule, plus repairs. I wonder how common it is for any of the pulleys to be failing at that many hours, or less? Thanks to all.

Spanner

Veteran Member

Ok, Talking "Pulleys" -

The idler pulleys used here are a plastic outer with a steel ball roller bearing moulded inside. The plastic outer has either "Vee" or "Flat" surfaces for the belt to run in/on.

That the bearing is moulded into the plastic pulley means it is replaced as a complete item. The bearings, alone, are not replacement items and they are sealed 'for life' and are not greasable.

Thus, they have a finite life-span the length of which, is influenced by heat, water & dust (mainly).

When the pre-loaded lubricant in those bearings wears out or is contaminated, by dust or water ingress (washing), the bearing will over-heat and seize (fail). the pulley will stop rotating but the belt will continue to travel along its pathway and over the stalled pulley. You can imagine, then, that the friction eventually causes the plastic pulley outer to 'melt' away and the belt can wear its way down right to the steel bearing cage.

This melting is often the 'burning smell' described by owners when they reporta belt-drive failure issue.

"I sensed a burning smell and then the drive stopped... " or similar. "I smelt burning and now the drive is noisy/rattly..." etc.

Occasionally, after the bearing cools down it can rotate again the next time the mower is used - But it now has a 'flat-spot' so it causes a vibration and noise associated with the sprung tensioner plate adjusting to compensate for the uneven pulley. I have seen idlers with two and even three flat spots. (Not common but nevertheless not impossible).

Consider that the idler pulley is not much different in diameter than the engine drive pulley and so the idler is rotating at approx engine speed (3,000-3,600 RPM) That's 50-60 revs per second. The vibration caused is a blur, but noisy.

So what I'm saying is - You do have to release/loosen the three idlers in order to install a new drive belt on your GX. The idlers are loosened to enable you to place the belt correctly inside the guides (retainers) which keep the belt in-line with the idler it is passing around.

Since you already have loosened the old idler it is no more effort to install a new idler at that time you are fitting the new belt. You now know you have new lubricant and clean bearings running your nice new belt.

Effectively, installing new idlers is akin to greasing the bearings. < Read that with a moment of lateral thinking!

In my experience, idlers last from 100- 250 hours and are best replaced before they fail. (Noise is the best diagnostic tool here).

Regards,

:wrench:

The idler pulleys used here are a plastic outer with a steel ball roller bearing moulded inside. The plastic outer has either "Vee" or "Flat" surfaces for the belt to run in/on.

That the bearing is moulded into the plastic pulley means it is replaced as a complete item. The bearings, alone, are not replacement items and they are sealed 'for life' and are not greasable.

Thus, they have a finite life-span the length of which, is influenced by heat, water & dust (mainly).

When the pre-loaded lubricant in those bearings wears out or is contaminated, by dust or water ingress (washing), the bearing will over-heat and seize (fail). the pulley will stop rotating but the belt will continue to travel along its pathway and over the stalled pulley. You can imagine, then, that the friction eventually causes the plastic pulley outer to 'melt' away and the belt can wear its way down right to the steel bearing cage.

This melting is often the 'burning smell' described by owners when they reporta belt-drive failure issue.

"I sensed a burning smell and then the drive stopped... " or similar. "I smelt burning and now the drive is noisy/rattly..." etc.

Occasionally, after the bearing cools down it can rotate again the next time the mower is used - But it now has a 'flat-spot' so it causes a vibration and noise associated with the sprung tensioner plate adjusting to compensate for the uneven pulley. I have seen idlers with two and even three flat spots. (Not common but nevertheless not impossible).

Consider that the idler pulley is not much different in diameter than the engine drive pulley and so the idler is rotating at approx engine speed (3,000-3,600 RPM) That's 50-60 revs per second. The vibration caused is a blur, but noisy.

So what I'm saying is - You do have to release/loosen the three idlers in order to install a new drive belt on your GX. The idlers are loosened to enable you to place the belt correctly inside the guides (retainers) which keep the belt in-line with the idler it is passing around.

Since you already have loosened the old idler it is no more effort to install a new idler at that time you are fitting the new belt. You now know you have new lubricant and clean bearings running your nice new belt.

Effectively, installing new idlers is akin to greasing the bearings. < Read that with a moment of lateral thinking!

In my experience, idlers last from 100- 250 hours and are best replaced before they fail. (Noise is the best diagnostic tool here).

Regards,

:wrench:

Spanner

Veteran Member

Ok, Talking "Washing" -

In his latest post Moe mentioned he 'pressure washed' mud & debris from around the transmission.

I'm just giving my view here - Water is the enemy of the Ride-on mower. (All brands)

More correctly perhaps, Ride-on's are not 'water friendly' machines.

So here's why:

Many places under the chassis of a ride-on are prone to catching/holding grass debris in the course of operation. These include the chassis rail sections, transmission housing, mower deck, steering assembly plate and even the upper surfaces of idler pulleys (dust mainly).

Water washing tends to flush grass debris downwards into crevices. Wet grass tends to become acidic and corrosive as it decays.

A more effective method of clearing debris from on/under your Ride-on is to use an air compressor with a long-nozzle air 'duster' gun.

Compressed air can 'fluff' out the grass and blow it out of crevices and chassis rails etc.

No moisture is left on components. That is a good thing.

Additionally, many mechanisms of the Ride-on mower are 'open-jointed' such as steering, belt clutch pivots, control linkages etc. Rear axle shafts are particularly prone to absorbing water into the wheel hub between the shaft and hub.

Over time this water has a negative effect on the condition of the various components.

Air on the other hand, can clear out all debris, more than water, and has no detrimental effect on components.

The underside of the mower deck is a different story. Washing is good and many manufacturers install a wash-port device for hose connection. Always grease your spindle bearings after washing under your mower deck.

An air compressor is a great investment in maintaining your Ride-on mower.

Just my :2cents:

Regards all,

:wrench:

In his latest post Moe mentioned he 'pressure washed' mud & debris from around the transmission.

I'm just giving my view here - Water is the enemy of the Ride-on mower. (All brands)

More correctly perhaps, Ride-on's are not 'water friendly' machines.

So here's why:

Many places under the chassis of a ride-on are prone to catching/holding grass debris in the course of operation. These include the chassis rail sections, transmission housing, mower deck, steering assembly plate and even the upper surfaces of idler pulleys (dust mainly).

Water washing tends to flush grass debris downwards into crevices. Wet grass tends to become acidic and corrosive as it decays.

A more effective method of clearing debris from on/under your Ride-on is to use an air compressor with a long-nozzle air 'duster' gun.

Compressed air can 'fluff' out the grass and blow it out of crevices and chassis rails etc.

No moisture is left on components. That is a good thing.

Additionally, many mechanisms of the Ride-on mower are 'open-jointed' such as steering, belt clutch pivots, control linkages etc. Rear axle shafts are particularly prone to absorbing water into the wheel hub between the shaft and hub.

Over time this water has a negative effect on the condition of the various components.

Air on the other hand, can clear out all debris, more than water, and has no detrimental effect on components.

The underside of the mower deck is a different story. Washing is good and many manufacturers install a wash-port device for hose connection. Always grease your spindle bearings after washing under your mower deck.

An air compressor is a great investment in maintaining your Ride-on mower.

Just my :2cents:

Regards all,

:wrench:

beenthere

Super Star Member

- Joined

- Aug 16, 2001

- Messages

- 18,612

- Location

- Southern Wisconsin, USA

- Tractor

- JD_4x2_Gator, JD_4300, JD_425, JD_455 AWS, added JD_455, JD_110, JD_X485(sold)

Agree 100% with the "no water" theory.. only air, AND after every mowing.

Don't put 'em away wet.

Don't put 'em away wet.