Well I thought I posted this yesterday but I guess I got busy and didn't hit post... /forums/images/graemlins/frown.gif

I reviewed in detail the BH and KK manuals. Both seem to do about the same but in a different manor. The BH uses the swivel under the Y as mentioned. The manual states to use a top link pin short enought to not hit the Y under the attachment point. This allows free motion under the Y(ok upside down Y). However the KK (as mentioned) has a stop on it to limit the swivel from pointing forward. If you look at the KK mower on its web site you can see it's standing straight up. This stop or limit allowes the mower to be picked up and keep the motion in one direction. IE with the KK it will allow the mower to move up in the rear (think of the tractor and cutter forming a smile /forums/images/graemlins/smile.gif, but will not let the mower fall below parrellel with the tractor, think if the tractor and mower forming a frown /forums/images/graemlins/confused.gif. I can see why you wouldn't want a frown, picture coming out of a small ditch or depression, if the mower was allowed to move down then it would probably scrape the ground and mow dirt. So in this case the KK would stop the downward travel and the rear wheel would come off the ground for a moment. The BH would probably do the same because the link should be adjusted for this, and whel pulled at the 45 degree angle the mower would not be allowed to fall. I think it's making sense to me...yall??? /forums/images/graemlins/grin.gif

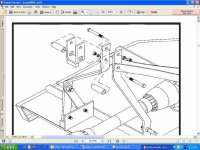

Either way reading the manuals brought to my attention there are specific ways the manufactors of these things want you to set up the links. If you read through the manuals you will see this. I've got my printed copies on file now. It did seem that on the KK this "flex" link was NOT an option but part of the standard mower kit. If you go to the KK web site and download the rotary cutter PDF file you can clearly see where they say to attach the flex link and you can clearly see the stop bar on the flex link itself, figure G.

Any better??? /forums/images/graemlins/grin.gif