muddstopper

Veteran Member

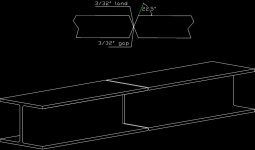

Seems like the harder I try, the more mistakes I made. I was cutting out the blade for my wood processor, measured it a dozen times, and still cut it wrong. I was cutting 3/4 plate to use for the wedges and managed to cut one 1/2inch to short. Each plate is supposed to be 15in long and then fitted together to make a full 30in piece. I didnt have a 30in piece so the reason for pieceing. Anyways, I dont have anything to cut any more pieces and just trying to figure out a way around since its not likely I can secure another piece until after the first of the year. My thoughts are to just gap the metal and fill it with weld. I have 6011 and 7018 x1/8 rods on hand. Where the joint will be will also be another wedge turned cross ways and the wedges are 7in wide. Right now the only option I have is wait for another piece of metal, or weld up the gap and use what I have. Little advise would come in handy right about now. I do have a carbon backing block to place behind the weld so I should be able to get a pretty good root pass.