AKKAMAAN

Veteran Member

Is it fixable? Do you have a picture of one done correctly? How far out of horizontal does it have to be? What about a shorter ram of similar strength and drop down the lower end (being careful not to bottom out?)

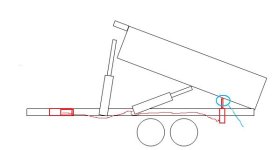

If you keep current cylinder, and mount a second similar cylinder, reduced diameter very possible, in the nose of the trailer. That will help to control both forces and the lowering speed. This second cylinder can not med pinned into the trailer. When the current cylinder "takes over" this front cylinder will disconnect from the trailer.

This 2nd cylinder shall be connected with a "T" to the line to the current cylinder.

This will of course slow down the start of the cycle.

With this arrangement, you can also replace the current cylinder with a smaller diameter cylinder.

A one way flow control needle valve is still a good idea to control/maintain a SAFE lowering speed.