OP

CDN Farm Boy

Veteran Member

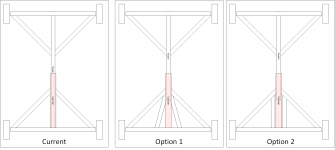

Correct me if I'm wrong, but location matters. The closer the cylinder attaches to the front of the box, the better. Lifting at the front edge of the box would need a lot less lift than lifting from the middle. Turning the cylinder and pushing from the back should or at least could, make for a more forward lift point on the box. A good thing. Course, this would also mean longer cylinder travel to achieve the same angle of dump. Seems like a longer cylinder would be easier and cheaper than building for less travel but higher total forces.

Or not.

That's exactly what rswyan was suggesting, but if my math was right, not quite that simple. At the same heights as I have now, with just reversing the mounting, due to the reduced effective angle of the cyl, would only have a net gain of about 550 lbs. Raising the bed 4" relative to the lower cyl and reversing the cyl would make a significant difference.

As for dump angle, this orientation would actually gain about 5 deg of dump with the same cyl.

Something still seems wrong with orienting the cyl this way to me. Aside from a couple people here, I've never seen one like this. Why are they not a more common design?