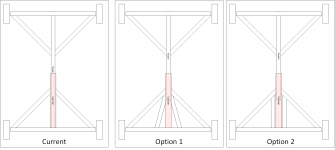

CFB, It looks like if you were to add some "long sills" as they are called on a truck dumper, right under your "lower frame", just like a dump truck, you could use this to "hang" some side plates down, then go across with a heavy (wall) pipe or sq tube? like 4" sch.80 or 4x4/3/8 wall (remember the forces this will see will be (approx) 45* to almost 90*) so it needs to be strong on more than one axis, pipe & sq. are good for this over any "I" or angle. This would be your new & lower location to mount your cly. If I've not explained this properly, think of an older grain dump (truck). They would often have this type of set up although usually with a cylinder on each side of the (truck) frame. This would also be an option for you. These new "long sills" should also be (in my guestimation) 6" chan @ about 10.5 lbs./ft. assuming that the cyl. would be mounted at about 1/3 of the span. Also the side plates that drop down to support your X tube for the cyl. mount needs to be somewhat of a large triangle also for the above described forces back & down.