fjellheimen

New member

- Joined

- Aug 28, 2019

- Messages

- 6

- Tractor

- John Deere 1040

Hi

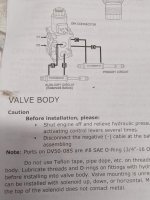

I'm in the process of adding a 3rd function for my grapple on an old John Deere 1040 using a 12v solenoid diverter valve.

When the solenoid doesn't get power oil flows from the bottom ports and through the two middle ports. However when the solenoid gets powered it stops oil flowing through the middle ports, but no oil flows through the two top ports. Any ideas on what the problem might be?

I'm in the process of adding a 3rd function for my grapple on an old John Deere 1040 using a 12v solenoid diverter valve.

When the solenoid doesn't get power oil flows from the bottom ports and through the two middle ports. However when the solenoid gets powered it stops oil flowing through the middle ports, but no oil flows through the two top ports. Any ideas on what the problem might be?