woodsmith

Bronze Member

I made a parking brake lever.

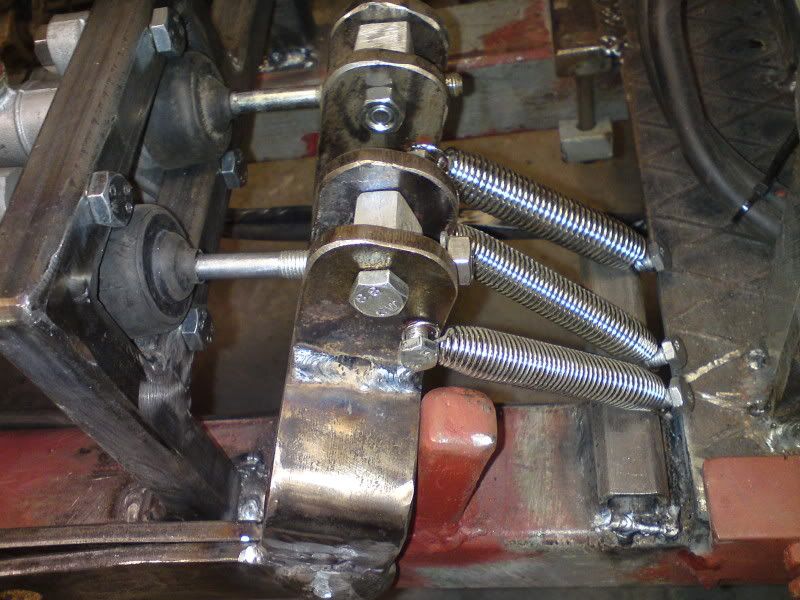

Brake off:

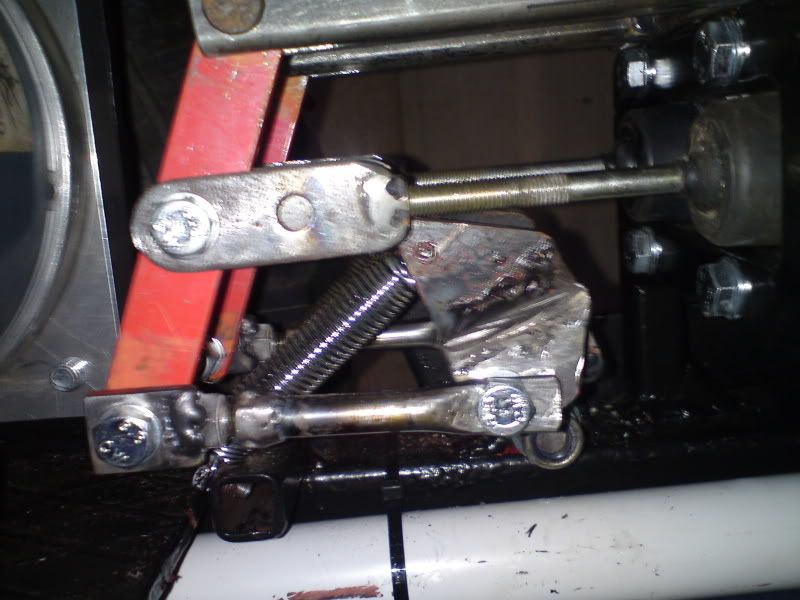

Brake on:

It works well enough to stop the tractor from rolling away but while playing I forgot to let off the brake before applying drive. The brake broke. The bolt in the pulley spokes was ripped out and the steel strap twisted all out of shape. I have now 'beefed' it up a lot but I might remake it in my usual 6mm steel. It will be fine for parking up though.

I also made the gear lever from some 20x2mm box tube.

The link is a bit of 5mm rod that I had spare. I formed eyes into the ends to fit the M8 bolts.

Trying it out I found that the curved part of the lever was rubbing the back of my knee while sitting so I adjusted it.

I shortened the rod and put a twist into the lever so it is further back.

The next thing was to make the brake pedal. That was more my usual over the top and over engineered part. :laughing:

I still need to make a bracket for the master cylinder and also I will need to bend the crank lever over a bit as the cyclinder is a little close to the edge of the pedal.

This is how it all looks from the driver's seat (excuse the view between my legs! :ashamed: ).

You can see how the brake pedal fits in

The gear lever, to the right, is forward for low gear. High gear is only a 1 1/2" backwards.

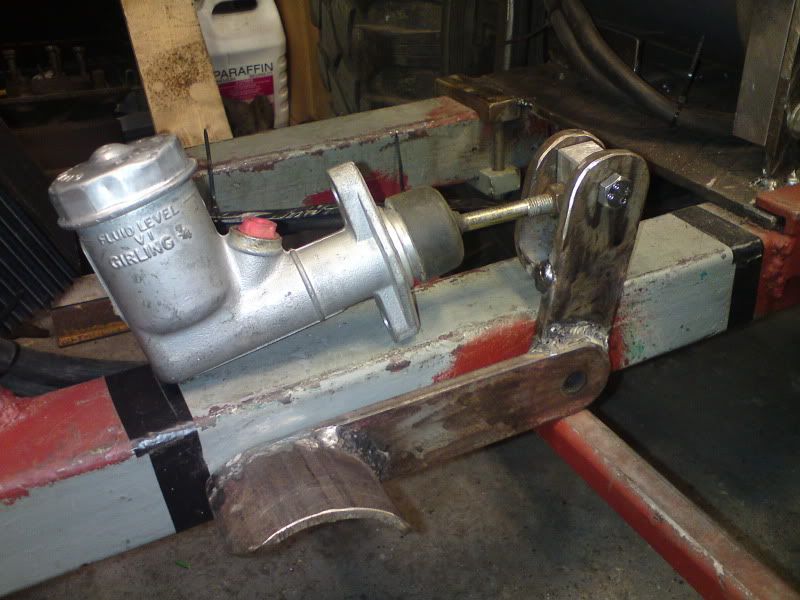

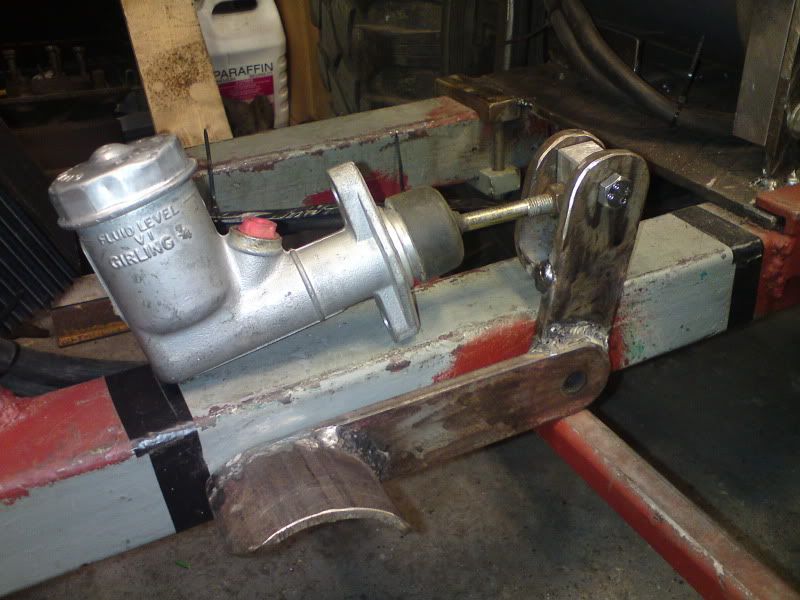

I also have this master cylinder.

It will sit low between the chassis rails and have a conventional hand brake lever over it. It will be plumbed in line with the foot brake working on the same hydraulic line so I won't leave it on when parked over night, the bolt in the pulley spokes will surfice for that.

I also tried the MR2 throttle pot.

It works but, like the slider pot, seems to have a dead area over the first 1/4 to 1/3 of the action. I am begining to wonder if it is controller programming.

Reading the manual I can see that I can reprogramme it with a £450 programmer or by manual methods with the flashing LED. However, it doesn't say how.

Brake off:

Brake on:

It works well enough to stop the tractor from rolling away but while playing I forgot to let off the brake before applying drive. The brake broke. The bolt in the pulley spokes was ripped out and the steel strap twisted all out of shape. I have now 'beefed' it up a lot but I might remake it in my usual 6mm steel. It will be fine for parking up though.

I also made the gear lever from some 20x2mm box tube.

The link is a bit of 5mm rod that I had spare. I formed eyes into the ends to fit the M8 bolts.

Trying it out I found that the curved part of the lever was rubbing the back of my knee while sitting so I adjusted it.

I shortened the rod and put a twist into the lever so it is further back.

The next thing was to make the brake pedal. That was more my usual over the top and over engineered part. :laughing:

I still need to make a bracket for the master cylinder and also I will need to bend the crank lever over a bit as the cyclinder is a little close to the edge of the pedal.

This is how it all looks from the driver's seat (excuse the view between my legs! :ashamed: ).

You can see how the brake pedal fits in

The gear lever, to the right, is forward for low gear. High gear is only a 1 1/2" backwards.

I also have this master cylinder.

It will sit low between the chassis rails and have a conventional hand brake lever over it. It will be plumbed in line with the foot brake working on the same hydraulic line so I won't leave it on when parked over night, the bolt in the pulley spokes will surfice for that.

I also tried the MR2 throttle pot.

It works but, like the slider pot, seems to have a dead area over the first 1/4 to 1/3 of the action. I am begining to wonder if it is controller programming.

Reading the manual I can see that I can reprogramme it with a £450 programmer or by manual methods with the flashing LED. However, it doesn't say how.