Jay4200

Veteran Member

- Joined

- Nov 23, 2005

- Messages

- 2,054

- Location

- Hudson/Weare, NH

- Tractor

- L4200GST w/ LA680 & BX2200D w/ LA211

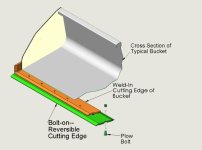

I am planning on welding a new cutting edge on my old FEL bucket. I got a used edge from a town plow and cut it to length. That is all great, but I can't decide which direction to place the cutting edge bevel.

Common convention seems to put the sharp edge facing down with the bevel on top, but that seems like that would put undue stress on the sharpened edge, especially while back-dragging (I do a lot of that) - with any downward angle at all on the bucket, all of the load stress is across the thinned metal of the sharpened edge. Putting the flat side up with the bevel on the bottom would allow the sharpened edge to be supported back into the blade, and would allow both pushing and backdragging with a bucket angle as high as the bevel w/o stressing the sharpened edge.

90% of what I do with my tractor is dozing, grading, and back-dragging rocky soil and/or gravel. Is upsidedown (bevel down) maybe a good idea? Are my edge-stress theories valid? I can't decide what to do.

Thanks - JayC

Common convention seems to put the sharp edge facing down with the bevel on top, but that seems like that would put undue stress on the sharpened edge, especially while back-dragging (I do a lot of that) - with any downward angle at all on the bucket, all of the load stress is across the thinned metal of the sharpened edge. Putting the flat side up with the bevel on the bottom would allow the sharpened edge to be supported back into the blade, and would allow both pushing and backdragging with a bucket angle as high as the bevel w/o stressing the sharpened edge.

90% of what I do with my tractor is dozing, grading, and back-dragging rocky soil and/or gravel. Is upsidedown (bevel down) maybe a good idea? Are my edge-stress theories valid? I can't decide what to do.

Thanks - JayC