Have you used one? Just curious how well they work?You could get a pond scoop.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

FELs and digging

- Thread starter SmallChange

- Start date

- Views: 20596

More options

Who Replied?

/ FELs and digging

#41

bdhsfz6

Elite Member

- Joined

- Apr 11, 2015

- Messages

- 3,661

- Location

- Northeastern Pennsylvania

- Tractor

- Kubota MX5800 HST & L6060 HSTC Formerly L6060 HST B7100 HST, L2550, L3010 HST, L3430 HST

I also have both. I usually leave the heavy construction grade bucket on but the extra weight cuts into the FEL lifting capacity.The issue with a light gage material bucket, versus a heavy gage excavation bucket is the light gage bucket has a single bottom sheet and digging with it (even with a tooth bar installed) can cause a smile in the bottom sheet that is hard to remove. Most dealers sell a new unit with a light gage bucket. I have both.

I attach a bucket attachment spade on my [AFFILIATE=1, nofollow=true, newwindow=true, title="Kubota"]Kubota[/AFFILIATE] L3400. That said, I'm very carful to make sure it's exactly centered on the FEL, and dig only when there's been a good rain and the earth is as soft as possible. I go in at a shallow angle from multiple directions, then more directly to break down the edges of the hole. This works fine. But I never try to plunge the thing in more vertically and then try to pry out a large chunk.

Attachments

5030

Rest in Peace

- Joined

- Feb 21, 2003

- Messages

- 28,967

- Location

- SE Michigan in the middle of nowhere

- Tractor

- Kubota M9000 HDCC3 M9000 HDC

Not an issue with either of my M9's. Plenty of lift capacity always.

SaddleBronc

New member

- Joined

- Sep 5, 2013

- Messages

- 22

- Location

- Duncan, OK

- Tractor

- Kubota M8560, JD 110TLB, New Holland C238 CTL

IMO, you are asking a good question, as there is a real difference between utility tractors and excavation equipment. I learned this in the military, but the market has changed a lot since then so here's my current real-world experience.

I own a JD 110TLB. This is a small backhoe intended for contractors, ranchers/farmers, etc. But don't let size fool you - it's a very stout example of a backhoe. The frame is more robust. The loader arms are massive with gussets and fishplates that aren't seen on utility loaders. The drivetrain is strictly hydraulic and very sturdy, again bigger in size and volume than other hydraulic systems. The hoe is simply a smaller version of that found on full-size backhoes, and it's just as robust as the loader.

I owned this and a very comparable JD 5300 w/loader at the same time. HP for the 5300 was higher but weight was similar. There was simply no comparison between what the two loaders would do when it came time to dig. I now own a considerably larger [AFFILIATE=1, nofollow=true, newwindow=true, title="Kubota"]Kubota[/AFFILIATE] M8560 w/loader, and even it can't match the 110TLB. I'll note that all the buckets interchange, so it's not a matter of bucket design.

You can spend a lot of money on attachments and features for your utility tractor to help it dig, but they'll mostly be band-aids and will likely disappoint.

If you're serious about digging, rent a backhoe for one of your more challenging jobs and feel the difference. Do this before you spend a lot of money upfitting your utility tractor.

I own a JD 110TLB. This is a small backhoe intended for contractors, ranchers/farmers, etc. But don't let size fool you - it's a very stout example of a backhoe. The frame is more robust. The loader arms are massive with gussets and fishplates that aren't seen on utility loaders. The drivetrain is strictly hydraulic and very sturdy, again bigger in size and volume than other hydraulic systems. The hoe is simply a smaller version of that found on full-size backhoes, and it's just as robust as the loader.

I owned this and a very comparable JD 5300 w/loader at the same time. HP for the 5300 was higher but weight was similar. There was simply no comparison between what the two loaders would do when it came time to dig. I now own a considerably larger [AFFILIATE=1, nofollow=true, newwindow=true, title="Kubota"]Kubota[/AFFILIATE] M8560 w/loader, and even it can't match the 110TLB. I'll note that all the buckets interchange, so it's not a matter of bucket design.

You can spend a lot of money on attachments and features for your utility tractor to help it dig, but they'll mostly be band-aids and will likely disappoint.

If you're serious about digging, rent a backhoe for one of your more challenging jobs and feel the difference. Do this before you spend a lot of money upfitting your utility tractor.

JethroB

Veteran Member

- Joined

- May 19, 2020

- Messages

- 2,341

- Location

- Really Deep Southeast

- Tractor

- Kubota L5460 HSTC Cab, MF 135 Diesel

Pond scoop, or called a dirt scoop around here. I have one I bought slightly used at a farm equipment graveyard for $200. (no FEL here) Definitely old school and it has it’s limitations but works well once you figure out its quirks. Dig a trench or skim going forward or scoop from a pile in reverse. People ask “why not a FEL”. Well currently they are back ordered for about a year, cost $6000, and I don’t have much use for one, I mostly mow.You could get a pond scoop.

5030

Rest in Peace

- Joined

- Feb 21, 2003

- Messages

- 28,967

- Location

- SE Michigan in the middle of nowhere

- Tractor

- Kubota M9000 HDCC3 M9000 HDC

Yours is about 1/3rd the size of my 2 M9's. I run R1's as well with cast centers.Pond scoop, or called a dirt scoop around here. I have one I bought slightly used at a farm equipment graveyard for $200. (no FEL here) Definitely old school and it has it’s limitations but works well once you figure out its quirks. Dig a trench or skim going forward or scoop from a pile in reverse. People ask “why not a FEL”. Well currently they are back ordered for about a year, cost $6000, and I don’t have much use for one, I mostly mow. View attachment 778384View attachment 778386

dhjmd

Bronze Member

- Joined

- Aug 12, 2020

- Messages

- 64

- Location

- Morton, IL

- Tractor

- Caterpillar 289D, New Holland TC24DA, Kubota Grand L6060 HSTC

I can at least give you my experience. I bought a NH TC24DA with 60” FEL smooth edge bucket back in 2004. That tractor with FEL weighs something like 1500 lb. I typically used for mowing using a 60” MMM. In 2010, I went to build a 28’x48’ outbuilding and had decided to put in a 4’ deep perimeter foundation. Our soil in central IL is a little bit of black dirt sitting on feet of clay. Instead of renting a Backhoe or a small Excavator, I dug that footing and foundation with this little tractor, something I wouldn’t realize the damage from until almost a decade later. I’m an engineer and should’ve known better. I’m also frugal and decided to use the investment/tool I had sitting there! It had done the job, but in 2020, I was moving some loose material and all of a sudden the tractor quit moving and sank in the middle. Yep, the tractor had literally split in two. Now, in 2014, I bought a Cat 289D CTL to work forestry on some other property we have. That machine weighs nearly 12K lb. It has an 84” tooth bucket but the moral is that this machine is purpose built for digging virgin ground. A compact, utility, or ag four-wheeled tractor is not purpose built to use a FEL (regardless of edge) for the same. There are lots of good points in this chain, if you choose to still do so. Taking small/thin bites, pre-processing to break up if possible, etc. Using a tooth bucket just gives you a false sense of security IMHO. Again, all lessons learned…and I have worked for Cat for 26 years now so have seen my share of what happens when the wrong tool is used for the job

JethroB

Veteran Member

- Joined

- May 19, 2020

- Messages

- 2,341

- Location

- Really Deep Southeast

- Tractor

- Kubota L5460 HSTC Cab, MF 135 Diesel

Huh? Your point? Oh yeah, always bigger, faster, stronger, better……Yours is about 1/3rd the size of my 2 M9's. I run R1's as well with cast centers.

Last edited:

5030

Rest in Peace

- Joined

- Feb 21, 2003

- Messages

- 28,967

- Location

- SE Michigan in the middle of nowhere

- Tractor

- Kubota M9000 HDCC3 M9000 HDC

My point is, you buy what you need to do a job correctly. Not on price but on capacity and you don't have that because you bought with your wallet.

yammerjammer

New member

- Joined

- Mar 5, 2022

- Messages

- 14

- Tractor

- Yanmar 2210

I just carved out a rock hillside with a light weight flat tooth bucket on a koyker 80. Went real slow and used the rippers when I could. Had very little space so bucket did most of the work.

Went slow but job is getting done. Just pushing along the top of the rock scraping a few inches at a time.

Might as well use it. If it breaks just fix it.

Went slow but job is getting done. Just pushing along the top of the rock scraping a few inches at a time.

Might as well use it. If it breaks just fix it.

Bentrim

Gold Member

- Joined

- Apr 22, 2020

- Messages

- 364

- Location

- York County, Pennsylvania

- Tractor

- Massey Ferguson 245, Massey Ferguson 14 Allis Chalmers G

When loaders (FEL) were first made most were very crude pieces. Some were mounted on the back of a tractor, some were mounted on the front with cylinders and cables to lift them, some were mounted on a tractor and basically that was all the tractor could be used for. Most of these has lift only with no down pressure and a manual trip bucket and the buckets were very narrow. Many after market manufacturers sprung up and when their gadgets failed they disappeared.

Most agriculture companies then started building Manure Loaders these were built for of course loading manure into a spreader, handling grain, fertilizer, snow and other light jobs around the farm. Most should not be used for earth moving as they were light construction and would break, bend, or fail. Even today they are still no meant for digging. Most of the time you can tell by how they are mounted. Are the frames heavy, are they full length of the tractor, or are they bolted to weak parts of the frame, do they take the stress off the tractor frame?

Construction equipment manufacturers found these to light for digging and companies started building heavier frame loaders that mounted under the rear axle and solidly on the front of the tractor. Some manufacturers made the loader and tractor as a package to get the strength required for digging and lifting heavy loads of soil high enough to put it on a truck. Get a chance go look at one, notice most now are built as a complete package and frames are heavy and strong. Most will have enough force to lift the tractor high off the ground.

Now with that said I'm not saying most "homeowner" grade loaders can't dig in the earth, but you are risking broken frames, mounts, and possible damage to the tractor to do so.

A backhoe is a specialized tool made for digging trenches. Again there are "homeowner" grade and industrial grade. A small one can do the job usually if the soil isn't too hard, but it will take longer to do the same job.

An example of that years ago our neighbor had a water line leaking and wanted to replace it. He called my father who took a JD 400 with a Brantly backhoe and attempted to dig up the pipe. A few hours later, after barely scratching the surface, he called me and asked if I could borrow a 580 Case TBL. I went over which took longer than digging the pipe out.

So in summing it all up go ahead it is your tractor, your investment, Use it as you see fit but when and if it fails don't blame the manufacturer for building a poor product unless they stated it can be used for excavation.

Most agriculture companies then started building Manure Loaders these were built for of course loading manure into a spreader, handling grain, fertilizer, snow and other light jobs around the farm. Most should not be used for earth moving as they were light construction and would break, bend, or fail. Even today they are still no meant for digging. Most of the time you can tell by how they are mounted. Are the frames heavy, are they full length of the tractor, or are they bolted to weak parts of the frame, do they take the stress off the tractor frame?

Construction equipment manufacturers found these to light for digging and companies started building heavier frame loaders that mounted under the rear axle and solidly on the front of the tractor. Some manufacturers made the loader and tractor as a package to get the strength required for digging and lifting heavy loads of soil high enough to put it on a truck. Get a chance go look at one, notice most now are built as a complete package and frames are heavy and strong. Most will have enough force to lift the tractor high off the ground.

Now with that said I'm not saying most "homeowner" grade loaders can't dig in the earth, but you are risking broken frames, mounts, and possible damage to the tractor to do so.

A backhoe is a specialized tool made for digging trenches. Again there are "homeowner" grade and industrial grade. A small one can do the job usually if the soil isn't too hard, but it will take longer to do the same job.

An example of that years ago our neighbor had a water line leaking and wanted to replace it. He called my father who took a JD 400 with a Brantly backhoe and attempted to dig up the pipe. A few hours later, after barely scratching the surface, he called me and asked if I could borrow a 580 Case TBL. I went over which took longer than digging the pipe out.

So in summing it all up go ahead it is your tractor, your investment, Use it as you see fit but when and if it fails don't blame the manufacturer for building a poor product unless they stated it can be used for excavation.

4570Man

Super Star Member

- Joined

- Apr 7, 2015

- Messages

- 19,096

- Location

- Crossville, TN

- Tractor

- Kubota M59, Kubota L3800, Grasshopper 428D, Topkick dump truck, 3500 dump truck, 10 ton trailer, more lighter trailers.

My point is, you buy what you need to do a job correctly. Not on price but on capacity and you don't have that because you bought with your wallet.

The loader on your tractor was put there for loading hay bales not digging ponds. They built dirt pans and dozers for doing that.

sd455dan

Super Member

- Joined

- Oct 23, 2012

- Messages

- 6,442

- Location

- North Idaho

- Tractor

- Rhino 554, Ford 550 TLB (JD X500, MTD, Gilson riding mowers) Ford 3000-Sold

Not sure on the Koyker 80, but on the K2 K3 and 200 +series FELs they designed the FEL to Tie into the rear axle with heavy supports, a large cross support in the middle where the FEL uprights are and then forward running supports that mount at the front of the tractor.I just carved out a rock hillside with a light weight flat tooth bucket on a koyker 80. Went real slow and used the rippers when I could. Had very little space so bucket did most of the work.

Went slow but job is getting done. Just pushing along the top of the rock scraping a few inches at a time.

Might as well use it. If it breaks just fix it.

View attachment 778428View attachment 778429

At least with This style of mounting, much of the stress/force is transferred to the rear axle and is spread out. These new tractors mostly ditched the design and mount mainly to engine side supports.

Koyker's older design May not be Pretty and limits engine access a bit, but if you are going to dig with a non industrial CUT chance of success is probably improved.

5030

Rest in Peace

- Joined

- Feb 21, 2003

- Messages

- 28,967

- Location

- SE Michigan in the middle of nowhere

- Tractor

- Kubota M9000 HDCC3 M9000 HDC

The loader on either of my tractors (using the HD excavation bucket) is certainly capable of dirt work. Considering what they weigh it's a non issue. I don't do much however. No need to.The loader on your tractor was put there for loading hay bales not digging ponds. They built dirt pans and dozers for doing that.

Never dug a pond anyway. Not in my wheelhouse.

yammerjammer

New member

- Joined

- Mar 5, 2022

- Messages

- 14

- Tractor

- Yanmar 2210

Even the flimsyest loader is still going to dig faster than a shovel. Just have to work within its limits.

Rip up a few inches at a time, then scoop it up with the loader. Might take a while but will certainly get done.

I dont care what size the digging machine or intended use is. It will break if not used within its limits.

Rip up a few inches at a time, then scoop it up with the loader. Might take a while but will certainly get done.

I dont care what size the digging machine or intended use is. It will break if not used within its limits.

Brushcutter1

New member

Often farmers, especially hobby farmers, use what they have. Back in the 70s Dad had a David Brown 990 with a fel. A friend asked if Dad would bring it over and bury a dead cow in his pasture while he was at work. I watched. At about 2 feet deep, progress got real slow. Dad rolled the cow into the bucket, took it to the edge of the field which happened to be the edge of a brushy canyon and dumped it. Then he filled the hole. I think he told his friend. I still have that 990. I also now have a 3 pt. backhoe for it. In the last 15 years or so we've had to bury 4 horses. Using the hoe to dig, and the loader to "fill" makes a hard job easier.

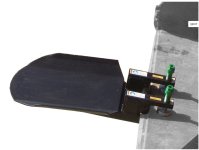

Look at the following image. On construction (read earth engaging equipment) machines the pins and pin bosses are oversized and frequently use replaceable bronze bushings. The bossess will be 1+ inch thick with gusseting. Now look at your tractor bosses. The are only 1/4 inch thick without gussets and light duty. Using your AG or residential quality tractor will result in premature wear and equipment damage like the image below. Your tractor isn't designed to handle the loads created in earth engaging work.I kind of think "front end loader" means an implement on the front end for picking up and moving loads, from a pile. I fear my little CUT bucket (with a straight edge) isn't meant for cutting into the earth, and if I try to do that, I should go easy, because I'm pushing it out of its intended comfort zone.

But I also think a "backhoe loader" that has teeth on the backhoe bucket and ALSO the front end loader bucket is indeed meant for cutting into the earth. So, it's heavier as well as having teeth.

These seem contradictory. So, how do you tell if a bucket on the front is intended for actual digging? Is it the teeth? Is it the fact that there's also a backhoe on the other end? Putting a tooth bar on my bucket could be taking a bit of a chance with it, right?

Enlighten me please? Thanks!

Attachments

5030

Rest in Peace

- Joined

- Feb 21, 2003

- Messages

- 28,967

- Location

- SE Michigan in the middle of nowhere

- Tractor

- Kubota M9000 HDCC3 M9000 HDC

That looks like more of poor maintenance than anything else. Not an issue with either of my units as I re-machined all the pivots and trunnions and fitted them with Thompson Linear roller bearings and alemite fittings. Even on my 2002, 6000 hour unit, all the pivots are tight with no slop. Neglecting equipment always has a price. On fact, both my tractors get greased every 10 meter hours. Grease is the cheapest commodity you can buy. Use it. Same applies to all my vehicles. Oil changes, filters and fluids get changed regularly and often.Look at the following image. On construction (read earth engaging equipment) machines the pins and pin bosses are oversized and frequently use replaceable bronze bushings. The bossess will be 1+ inch thick with gusseting. Now look at your tractor bosses. The are only 1/4 inch thick without gussets and light duty. Using your AG or residential quality tractor will result in premature wear and equipment damage like the image below. Your tractor isn't designed to handle the loads created in earth engaging work.

Like I said, I don't dig ponds anyway. I do however load round bales on tractor trailers in the growing season but always with my double bottom excavation bucket and they weigh in the excess of 1000 pounds per.

aircommuter

Platinum Member

- Joined

- Nov 26, 2012

- Messages

- 750

- Location

- coulterville,ca

- Tractor

- case 570lxt, JCB 1550B, Gradall 534c, Hyster C612B,Ford 445A

A loader is what the name implies. If it has teeth then it can be used for for both. If you have sandy soil you can get by with more.