cowpen

Member

I found this site a couple of months ago searching for tips and techniques as I planned my pole barn project. What a fantastic resource TBN is! I've literally spent hours on end reading and learning about the various projects the members here have undertaken and were generous enough to share on the forum. Good stuff - I'm learning a lot.

I've been planning to build a barn for a long time. But life always seemed to get in the way, and the barn just kept slipping down the ol' priority list. Now, between the swamp buggy, ATV's, boat, other toys, and soon a tractor, I've got no choice but to get busy! I have lots of questions, but first I'll explain where I'm at in the process.

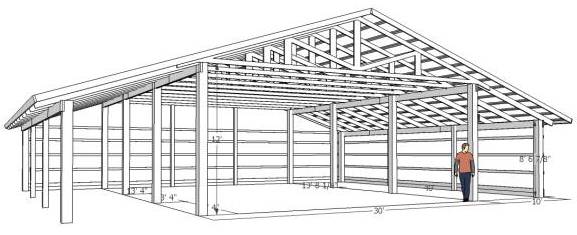

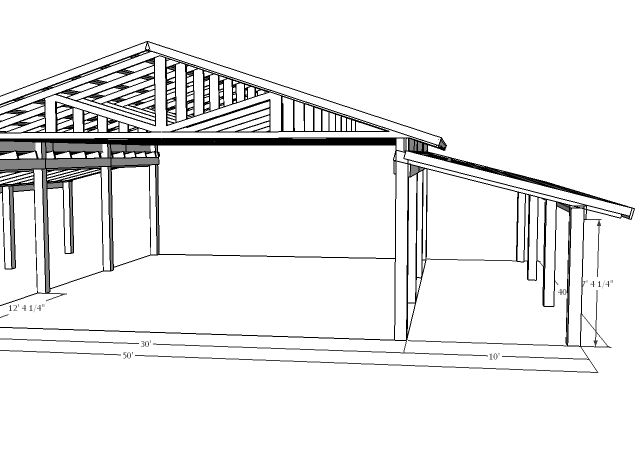

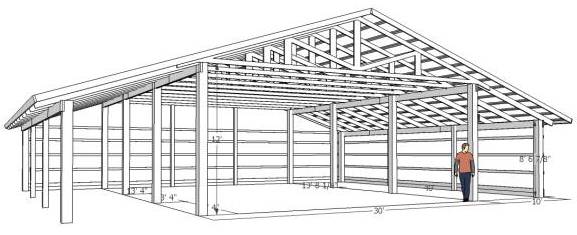

The barn will be 30' wide by 40' deep by 12' high under trusses, with 10' wide sheds on each side. Total is 40' x 50'. It's hot & humid here almost year 'round, so I'll be closing in the north and east walls only - leaving the other two sides open to allow some breeze. I'll also have 2 foot overhangs on the eaves and gable ends.

I've been hashing out the design using a free program called Google Sketchup (very slick, very easy check it out). Here's what the basic frame will look like:

I've been planning to build a barn for a long time. But life always seemed to get in the way, and the barn just kept slipping down the ol' priority list. Now, between the swamp buggy, ATV's, boat, other toys, and soon a tractor, I've got no choice but to get busy! I have lots of questions, but first I'll explain where I'm at in the process.

The barn will be 30' wide by 40' deep by 12' high under trusses, with 10' wide sheds on each side. Total is 40' x 50'. It's hot & humid here almost year 'round, so I'll be closing in the north and east walls only - leaving the other two sides open to allow some breeze. I'll also have 2 foot overhangs on the eaves and gable ends.

I've been hashing out the design using a free program called Google Sketchup (very slick, very easy check it out). Here's what the basic frame will look like: