Mrwurm

Veteran Member

- Joined

- Jan 20, 2002

- Messages

- 1,569

- Location

- South East Michigan

- Tractor

- New Holland TC30 Hydro 4x4, Gravely Zero Turn Mower

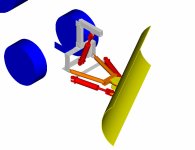

"But being a mechanical engineer, half the fun of this project is designing it"

Yep, I had to design and build all the brackets for my setup. Took about two weeks and was alot of fun. I sold the tractor, maybe I'll do it again for my new tractor.

Yep, I had to design and build all the brackets for my setup. Took about two weeks and was alot of fun. I sold the tractor, maybe I'll do it again for my new tractor.