WhiteRock

Silver Member

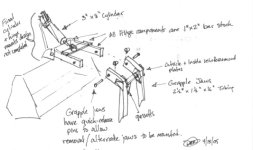

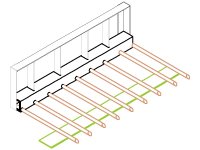

I am designing a grapple/rake bucket for my tractor (Kubota M9000, FEL LA1251A). The doesn't matter, but it will give folks an idea where my thoughts are coming from. Yes, I could buy one, but I wanted to design and build one.

I started this thread for design discussion (in the event any folks are interested) and to not hijack other project progress discussions

I am currently working on the rake/bucket portion and doing the grapple arm and hydraulics design in my spare time (near 0).

I am not as skilled as the TBN'er here so I have to design and draw. But I enjoy that. I am drawing in a way that I can post on the web. I do not have the skill to totally engineer a grapple, but you never know what one can learn here. I might before it is over.

I have done some work on the geometry of the grapple arm and cylinder pivot locations. I wrote a simple spread sheet to allows me to plug in placement values and it will compute my cylinder stroke. If there is interest I can try to post what I have.

Additions I intend to add to the spread sheet are:

- specify open close angle, have it compute stroke

- specify cylinder diameter and psi, have it compute closing/open force

- other associated grapple design info

Currently I would like to dig up some mechanical physics concepts and compute the pinching force of the grapple while being pushed by a cylinder at an angle.

If this stuff is already out there, maybe I just need pointers.

I will stop here to see if there is any interest in this sort of thing. I just thought it might generate some interesing ideas and reference material for build-it-yourself grapple folks.

I started this thread for design discussion (in the event any folks are interested) and to not hijack other project progress discussions

I am currently working on the rake/bucket portion and doing the grapple arm and hydraulics design in my spare time (near 0).

I am not as skilled as the TBN'er here so I have to design and draw. But I enjoy that. I am drawing in a way that I can post on the web. I do not have the skill to totally engineer a grapple, but you never know what one can learn here. I might before it is over.

I have done some work on the geometry of the grapple arm and cylinder pivot locations. I wrote a simple spread sheet to allows me to plug in placement values and it will compute my cylinder stroke. If there is interest I can try to post what I have.

Additions I intend to add to the spread sheet are:

- specify open close angle, have it compute stroke

- specify cylinder diameter and psi, have it compute closing/open force

- other associated grapple design info

Currently I would like to dig up some mechanical physics concepts and compute the pinching force of the grapple while being pushed by a cylinder at an angle.

If this stuff is already out there, maybe I just need pointers.

I will stop here to see if there is any interest in this sort of thing. I just thought it might generate some interesing ideas and reference material for build-it-yourself grapple folks.