Let me put it another way:

Build what you want, for you. We'll help where we can. Just don't expect everyone here to jump in on your project with your enthusiasm.

Bonus idea for you:

Making something the least expensive way that still works is what manufacturers do, and they have a team of experienced people doing it. The fact they make enough at the end of the day to keep the lights on and buy lunch is simply survival. Thinking you can teach yourself how AND do it for less is not realistic, no matter how hard you want it be.

It can be fun. It can get you something no-one makes for you. It can take you from something you already have closer to what you need. But don't think that beating the pros at their own game will be easy.

I mentioned before that beating with pros is not in my interests. Neither I believe that they charge too much. They do what they have to do. But if I can save the labor, the business expensess, and the shipping expenses that a commercial model has, and at some point to have a model with BOM and instructions that someone else can replicate, I will be satisfied. For example you can check the

CEB PRess we built in Open Source Ecology. Since it was done for a compresses earth block machine, a

grapple will be a toy. I really have no expectations from people. There is not much anyway. I am a little confused in some points (like why some designs have pins when some grade 8 bolts can offer similar function) but nothing much really. Last week I had no idea what a

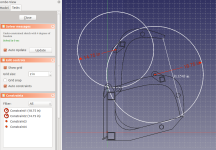

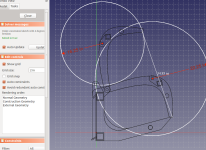

grapple was, today I have a 80% done CAD design.

About plasma cutting. Not yet. I see GREAT reviews on the CUT50 models that cost $250, that will suffice on 3/8" steel. I do not calculate it cost because I am going to buy one soon anyway (I have developed a CNC machine that I want to add the Plasma on when I overcome the Torch Height Controll obstacle). I really do not think these are problems.

Similarly when I tryied to finance a tractor few months ago, and FSA rejected my loan application, I end up fabricating a log arch to use with my ATV, and I had never welded before. Seriously I went to HF and bought a flux welder. The log arch still works, (well, it just retired since I got the tractor with a winch).

My "dissapointment" is when simple people -not pros- are not wiling to share a CAD file. Which is what motivates me. When I will finish the CAD, it will be available to whoever wants to jump start. 3 people refused to give me their designs. Whatever, I spent these 2 raining days in front of the computer and I have it almost ready. Take it from there, and improve it.

You say that I will have to add 50% cost to my projected one. MAybe, maybe not. Thats why I research, and thats why I CAD. To avoid mistakes in real life. But still, I may make some mistakes. When I document everything, the next one guy, will not make the same ones. Thats one step forward.