Xfaxman

Super Star Member

- Joined

- Feb 8, 2013

- Messages

- 13,280

- Location

- Guthrie, OK

- Tractor

- Toolcat 5610 G - Bobcat V417 - TORO+Loader

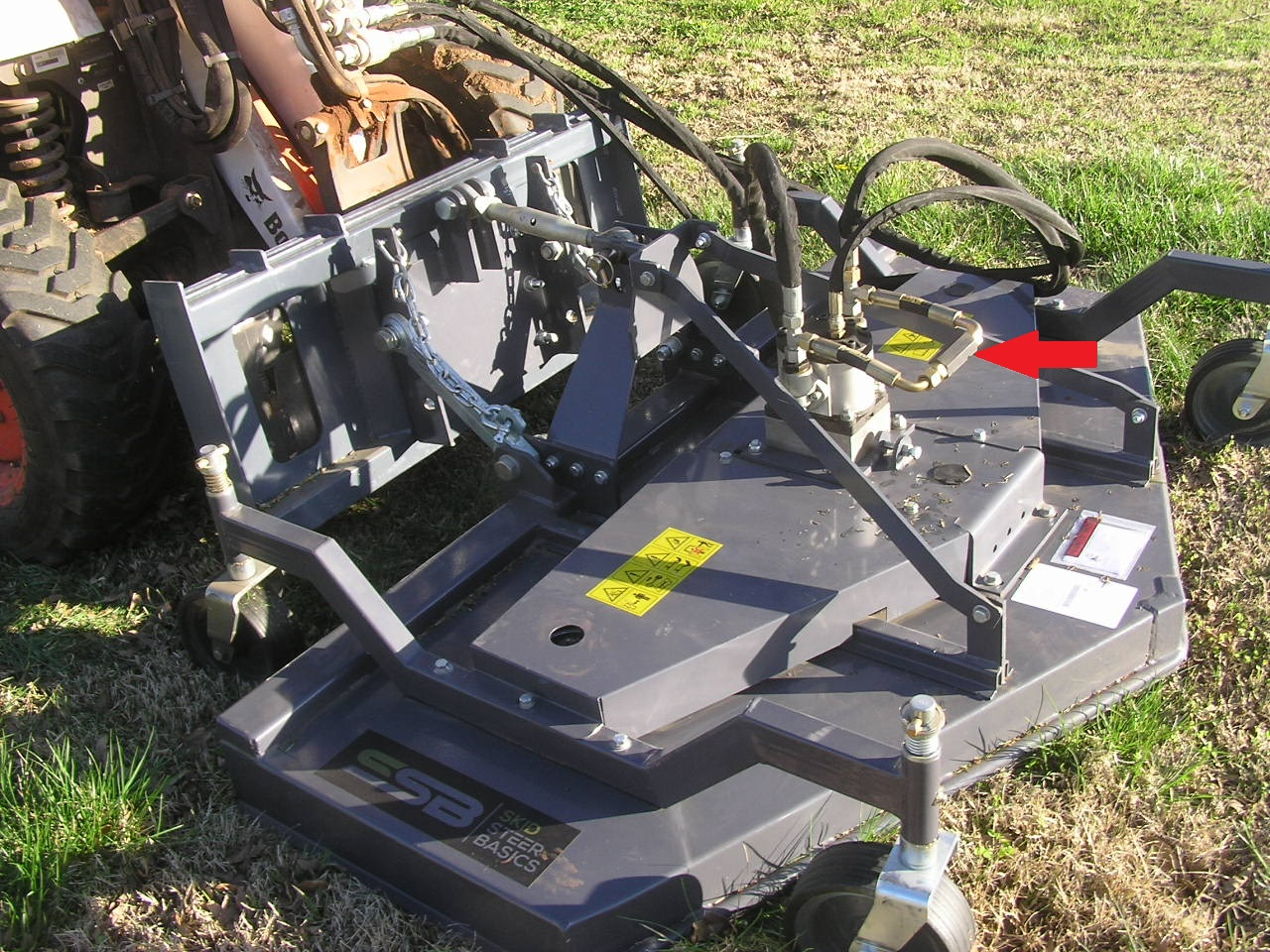

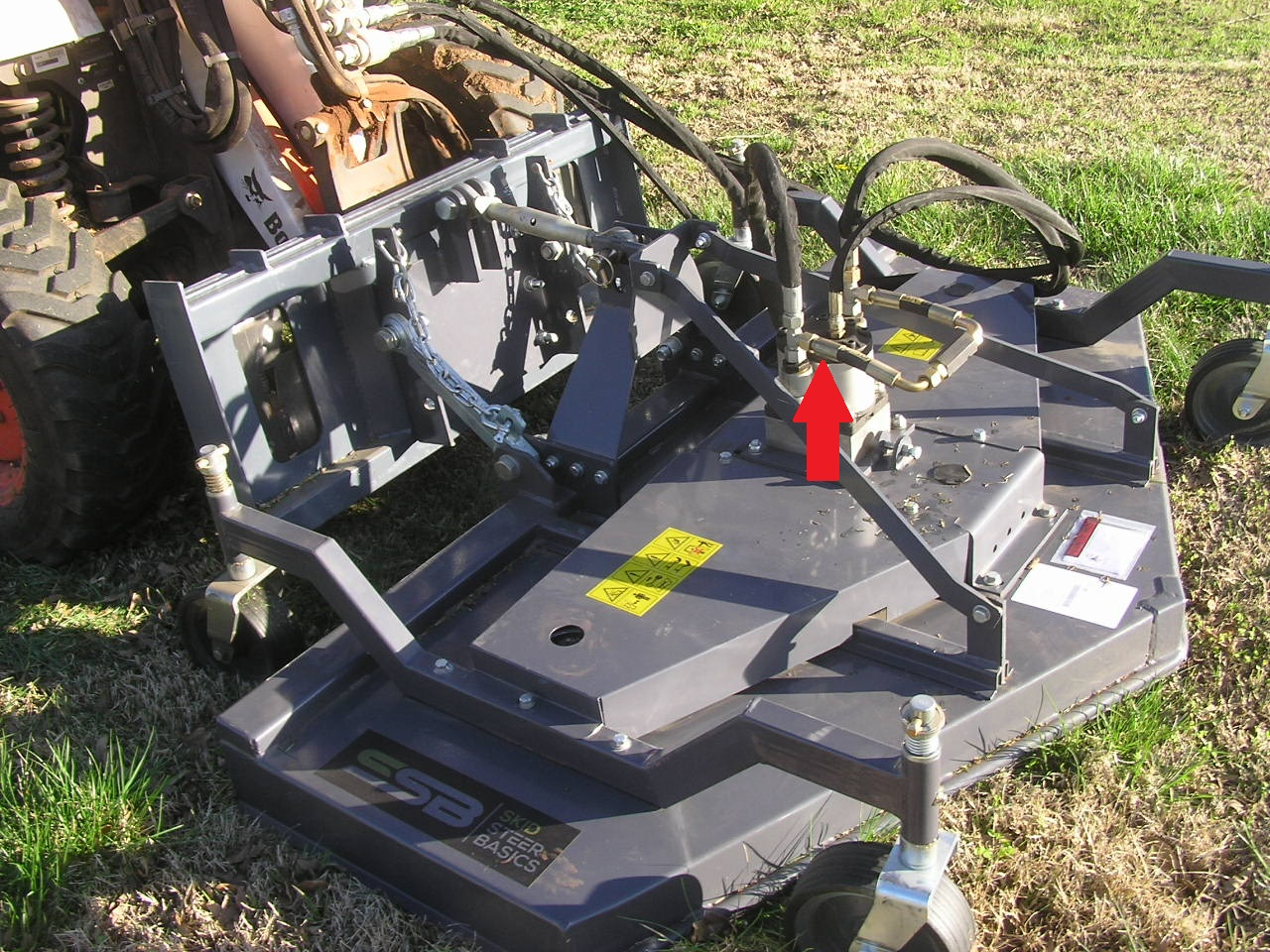

Have a finish mower on the Toolcat. It has a one way valve to prevent the blades from turning the wrong way. I think it might also let the motor spin down when aux hydraulic flow is shut off.

Last time I mowed the back yard one blade hit a root growing up on the surface. That stopped all rotation and the pressure side hose to the one way valve blew apart.

My question is, is there a combination fast acting pressure relief valve with a one way flow valve built in that would replace the existing one way valve and prevent blowing the hose again?

Last time I mowed the back yard one blade hit a root growing up on the surface. That stopped all rotation and the pressure side hose to the one way valve blew apart.

My question is, is there a combination fast acting pressure relief valve with a one way flow valve built in that would replace the existing one way valve and prevent blowing the hose again?

Last edited: