Homebrew

Bronze Member

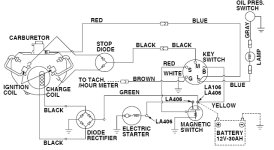

I was brush cutting in the woods, backed up and a large stick wedged up into the engine compartment and pulled apart some wires. The PT immediately stopped and I got nothing when I turned the key. After I got the stick removed, I saw that a connector had been pulled apart as well as a wire to the fan and perhaps another wire. Got the connector back together and it started and got it back to the garage. I know where the fan wire goes....I turned the key on and touched this wire to the connector and the fan started. THe problem is that it looks like there's an additional wire with a connector on it that I can't figure out where it goes. Maybe it goes to the taped wire in the picture. Anyone know if this wire is supposed to be connected to anything or is for diagnostic purposes? The picture shows arrows to the two wires in question (the one with a connector and one taped up). It sure doesn't look like the one with the connector pulled out of the one with the tape.