Looking4new

Super Star Member

- Joined

- Apr 8, 2012

- Messages

- 10,175

- Location

- Northern Ontario, Canada

- Tractor

- 2012 Kioti CK27HST w/cab

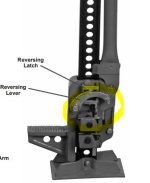

I just bought a farm jack (Motormaster 3-ton) and lifted one axel of my tractor and I can't get it to lower. Does anyone have tips on lowering a stuck farm jack? I can get the handle to move the full range of motion, it just seems like the pin is not entering the lower hole like it is supposed to.

Raise the handle ALL the way up to where it will come in contact with the main I-beam. Keeping ALL your body parts that you want to keep away from the jack and the vehicle, grab the handle loosely and fling it down. The jack should do the rest. It will bang, bang all the way to the bottom, if the pins are not seized.