plowhog

Elite Member

- Joined

- Dec 8, 2015

- Messages

- 3,211

- Location

- North. NV, North. CA

- Tractor

- Massey 1710 / 1758, Ventrac 4500Y / TD9

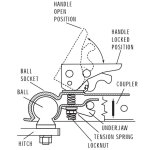

I have constant problems with my hitch ball / coupler connections. No matter how I seem to manipulate the coupler latch device, the coupler does NOT want to come free of the ball as I jack the trailer up to disconnect. This is an ongoing problem and it nearly caused a disaster.

I brought a 4,000 lb load of gravel home using my dump trailer. Put blocks down, then tried to jack it using the hand crank. What a joke-- no chance. To make it worse it was on a slight side incline and I was on the downhill side. Got my floor jack to "help it" go up while I cranked. But then the coupler latch got hung up and the ball would not release. Instead of separating, the rear of my pickup truck started going up along with the trailer tongue as I jacked.

As I must do frequently when disconnecting, I got a pipe and pried the coupler latch upward a tiny additional amount, and all hell broke lose. The coupler/ball broke free, the rear of the truck rose further, the tongue shifted sideways, my blocks collapsed due to the sideways motion, and everything came crashing down. It was very close to almost landing on my leg and foot and I realized how stupid I was to be on the downhill side of something on a bind.

Is there some magic to couplers and balls? Before jacking I lift the coupler latch up and slide a pin in to hold it up. There is a special pin slot seemingly designed just for that. But it always seems to "hang up" and then I need to whack the coupler latch a bit more or pry it to get it to separate.

I brought a 4,000 lb load of gravel home using my dump trailer. Put blocks down, then tried to jack it using the hand crank. What a joke-- no chance. To make it worse it was on a slight side incline and I was on the downhill side. Got my floor jack to "help it" go up while I cranked. But then the coupler latch got hung up and the ball would not release. Instead of separating, the rear of my pickup truck started going up along with the trailer tongue as I jacked.

As I must do frequently when disconnecting, I got a pipe and pried the coupler latch upward a tiny additional amount, and all hell broke lose. The coupler/ball broke free, the rear of the truck rose further, the tongue shifted sideways, my blocks collapsed due to the sideways motion, and everything came crashing down. It was very close to almost landing on my leg and foot and I realized how stupid I was to be on the downhill side of something on a bind.

Is there some magic to couplers and balls? Before jacking I lift the coupler latch up and slide a pin in to hold it up. There is a special pin slot seemingly designed just for that. But it always seems to "hang up" and then I need to whack the coupler latch a bit more or pry it to get it to separate.