I use the Lock-N-Lube, short and long version on a 20 Volt DeWalt battery gun and it works GREAT. No fuss, no muss. I buy the large boxes of shop rags, and use a throw away cheap paint brush to wipe off any old grease before it gets all over me. I carry a small plastic container to wipe the brush into, so I can save some of the old grease in case I need to apply some to rusted metal or whatever...

After doing one side of the loader, I will then wipe any leftover dirty or new grease that is present around the pin with a shop rag.

This process helps keep the mess less than otherwise. I also make a point of cleaning each zerk before any grease is pumped in. . I usually do 3-4 pumps, and look for the same signs of fresh grease showing at the pin. I use the red grease sometimes, marine too, or whatever is available in a case of cartridges, preferably on sale.

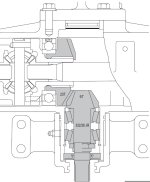

The only zerk that's weird on the DK series is the center of the front axle pivot. I could probably fill it with buckets of grease, BUT my dealer says to just do the usual, 2-3 pumps.

Greasing helps force me to check over the entire tractor on a more regular basis, which is a good thing! :thumbsup: