You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How would you repair this?

- Thread starter Shield Arc

- Start date

- Views: 4478

/ How would you repair this?

#1

D

Deleted member 216442

Guest

I broke a Lenox blade for my Ellis 1800 saw. How would you make this repair?

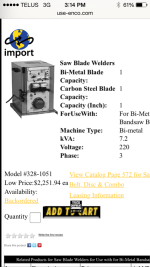

I would cut or grind the ends straight and reweld it using a blade welder found on some quality bandsaws, which also have grinders and annealers to complete the job. If you don't anneal it it will crack again. The welders hold them coplanar and push them together while a pulse of welding current is applied. The bulging weld has to then be ground flat and annealed.

Shield Arc

Super Member

Oh God, I'm the world's worst solderer / brazer!Square and scarf, Silver braze Clean up anything proud.

Just the same as making up a new one.

How about this?I would cut or grind the ends straight and reweld it using a blade welder found on some quality bandsaws, which also have grinders and annealers to complete the job. If you don't anneal it it will crack again. The welders hold them coplanar and push them together while a pulse of welding current is applied. The bulging weld has to then be ground flat and annealed.

Attachments

Big Barn

Super Member

- Joined

- Aug 20, 2013

- Messages

- 6,874

- Location

- Victoria, B C

- Tractor

- More than 40 over the years. Ten at any one time. Mostly Ford and New Holland

Shield Arc

Super Member

WOW! That's almost as much as I paid for the saw.:laughing:

That's almost as much as I paid for the saw.:laughing:

Mysfyt

Platinum Member

Nice tig job! Did you use stainless filler rod? I've got the same saw you have and I'd encourage you to try a vari-tooth blade such as a 5-8 in a bimetal. It will eliminate a lot of vibration.

Shield Arc

Super Member

Mysfyt where do you buy your blades at? I have the hardest time finding them. I just bought a dozen Lenox blades. So far I'm not impressed!:thumbdown: This blade broke about a month ago, it started cracking at the top of the blade, not at the teeth!

Yes I used ER 312 stainless steel.

Yes I used ER 312 stainless steel.

Attachments

dstig1

Super Member

- Joined

- Apr 7, 2010

- Messages

- 5,016

- Location

- W Wisc

- Tractor

- Kubota L5240 HSTC, JD X738 Mower, (Kubota L3130 HST - sold)

Have you ever checked tension on the BS blade? There are tension meters you can get for not too crazt money. Iturra has them (focused on WW applications, but tension is tension in a BS blade)... I'm just wondering if you are way over-stressing it by accident. Lennox is known for good blades. I have one of their sawzall blades and it is incredible compared to the usual Milwaukee or other stuff. But a defective batch is also a possibility.

Besides...a REAL MAN OA welds stuff like that, and doesn't leave all that ugly filler to grind away. A quick wipe with a scotchbrite pad should be all you need to get the weld flush with the blade... :laughing:

:laughing:

Besides...a REAL MAN OA welds stuff like that, and doesn't leave all that ugly filler to grind away. A quick wipe with a scotchbrite pad should be all you need to get the weld flush with the blade...

Arc weld

Veteran Member

You should get warranty on the blade. A new Ideal blade welder only runs about $250,000 and then you just need the grinder and the blade shear for a few thousand more. Should be pocket change for Shield Arc. Then you can buy 250' bulk coils of blade. My last job sold M.K. Morse (USA) blades and a lot of shops preferred them over Lenox. I liked the sales rep. He said they have 5 Ideal blade welders. Lenox moved production to China and I think quality suffered a bit. Wikus (Germany) are also really good blades.

Then you can buy 250' bulk coils of blade. My last job sold M.K. Morse (USA) blades and a lot of shops preferred them over Lenox. I liked the sales rep. He said they have 5 Ideal blade welders. Lenox moved production to China and I think quality suffered a bit. Wikus (Germany) are also really good blades.

Saw blades, hole saws, circular saw blades, and recip blades: The M. K. Morse Company provides professional quality metal cutting blades and power tool accessories.

Saw blades, hole saws, circular saw blades, and recip blades: The M. K. Morse Company provides professional quality metal cutting blades and power tool accessories.