MadReferee

Elite Member, Rest in Peace

- Joined

- Apr 28, 2003

- Messages

- 3,862

- Location

- New Hampshire

- Tractor

- Kubota B2710, IH TD6-62 dozer with Drott 4n1 bucket loader

First of all there is nothing wrong with your spool valve, it just may not be the right one.

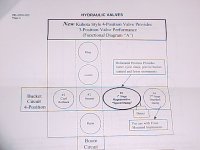

Check the ID tag on the loader joystick valve to see that it is an L2213A and not the L2203 which is a 3-way valve. I believe that the LA723 loader now comes standard with the L2213A 4-way valve but yours may be the L2203. This will definitely explain your problem. One of the links than ronjhall gave will explain what is happening.

The fact that it worked correctly in one direction tells me that you probably do not have to bleed/prime the center hose and that the problem is most likely the valve being 3-way instead of 4-way.

Check the ID tag on the loader joystick valve to see that it is an L2213A and not the L2203 which is a 3-way valve. I believe that the LA723 loader now comes standard with the L2213A 4-way valve but yours may be the L2203. This will definitely explain your problem. One of the links than ronjhall gave will explain what is happening.

The fact that it worked correctly in one direction tells me that you probably do not have to bleed/prime the center hose and that the problem is most likely the valve being 3-way instead of 4-way.