Xfaxman

Super Star Member

- Joined

- Feb 8, 2013

- Messages

- 13,282

- Location

- Guthrie, OK

- Tractor

- Toolcat 5610 G - Bobcat V417 - TORO+Loader

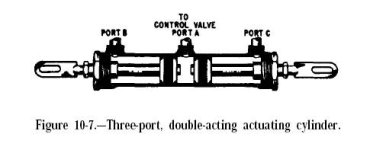

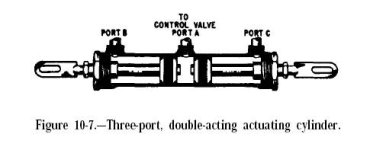

This is would work. Port A, extend. Connect port B and C with a tee to retract. The cylinder would be solidly mounted in the center. The rods could be the pins.

Pictures from Google Image Search

But don't know where you could find one the right size, probably could have one made by a good hydraulic shop.

Pictures from Google Image Search

But don't know where you could find one the right size, probably could have one made by a good hydraulic shop.