LD1,

So far, this analysis will probably result in a cylinder larger than you need.

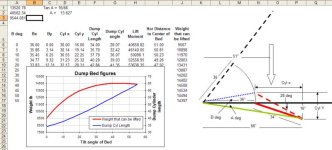

To calculate this more accurately, you need to approach it from the standpoint of torque rather than simple forces. Torque takes into consideration the locations of the pivot point, various centers of gravity, location of the two cylinder attachment points, and load behind the pivot point, if any. For example, that horizontal force component of your cylinder in which no one was really interested in actually works in your favor if the cylinder base is attached below* the pivot point. The torque approach also considers the weight supported by the pivot point which does not need to be lifted by the cylinder. The calculation is simple and amounts to the fact that the sum of all clockwise torques about the pivot must exceed the sum of all counterclockwise torques. Looking at your trailer from the left side, the weight of the trailer bed in front of the pivot causes a CCW torque and the weight of the trailer behind the pivot causes a CW torque. Their respective torques are their respective weights times the HORIZONTAL distances of the centers of gravity from the pivot. Similiarly for payloads in front and behind the pivot. The vertical component of the cylinder times the horizontal distance between its attachment to the bed and the pivot point is a CW torque. So is the horizontal cylinder force component times its base attachment point distance below the pivot. Try different cylinder sizes at max pressure and find one where the CW torque is greater than the CCW torque.

*Vertically below but not necessarily directly below

Quarencia,

That's bad! You'll have Mr. Mohr circling in his grave.

John