hbarski

Bronze Member

- Joined

- Apr 3, 2005

- Messages

- 69

- Location

- Tenn/Arkansas

- Tractor

- 3930 Ford/Newholland Mitsubishi MT2001D CASE 580 CK

<font color="blue"> "Currently, the valve has an inlet port, an outlet port, and 4 work ports (the work ports connect to the cylinders). By removing the plug and inserting the power beyond sleeve, you now have added an additional outlet port. This port is the power beyond port that allows fluid to flow to the next valve." </font>

I have you up to here.

<font color="blue"> "The "old" outlet port is still there and now becomes the return to tank port, and you still have the the inlet port." </font>

Now I'm lost.........

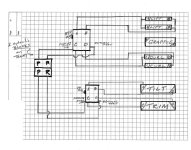

If I use the old "outlet port", where do I get my pressure from? I have reposted an attachment showing my system. Both systems appear to be independent except for the blocks at the tranny.

I have you up to here.

<font color="blue"> "The "old" outlet port is still there and now becomes the return to tank port, and you still have the the inlet port." </font>

Now I'm lost.........

If I use the old "outlet port", where do I get my pressure from? I have reposted an attachment showing my system. Both systems appear to be independent except for the blocks at the tranny.