hazmat

Elite Member

- Joined

- Feb 12, 2002

- Messages

- 4,051

- Location

- West Newbury, MA & Harrison, ME

- Tractor

- Kubota L5460HSTC

Inpsector has it right.

Generally PTO equipment comes with a long PTO shaft that must be trimmed to fit the particular tractor. There is no standard on distance from the end of the lift arms to the PTO spline.

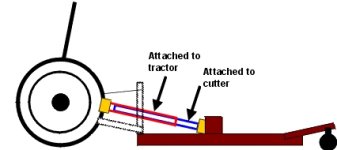

If you do buy a new PTO implement - check the length by sliding the tractor half of the shaft off & installing that on the tractor. Hold it parallel to the half of the shaft still on the implement. Then move the three point thru it's full range of motion & check for interference. If you need to cut it, mark it at the lift position where the shaft is shortest. Usually leave as much overlap as possible at this point.

There are a few threads on the subject (try a search on shaft or cutting PTO) with some pics and favorite cutting devices (a sawzall usually gets the job done).

Generally PTO equipment comes with a long PTO shaft that must be trimmed to fit the particular tractor. There is no standard on distance from the end of the lift arms to the PTO spline.

If you do buy a new PTO implement - check the length by sliding the tractor half of the shaft off & installing that on the tractor. Hold it parallel to the half of the shaft still on the implement. Then move the three point thru it's full range of motion & check for interference. If you need to cut it, mark it at the lift position where the shaft is shortest. Usually leave as much overlap as possible at this point.

There are a few threads on the subject (try a search on shaft or cutting PTO) with some pics and favorite cutting devices (a sawzall usually gets the job done).