As Kenny mentioned, Tyvek breathes, which makes it an

AIR barrier but

NOT a VAPOR barrier. Plastic is

BOTH, because

NOTHING passes it (unless you make

LOTS of holes in it

)

Here's the main thing to watch out for - when you heat a space, the moisture in it wants to leave - water vapor is so fine it will go thru pretty much

ANYTHING that isn't non-permeable. So the moisture in the room tries to exit thru anywhere it can.

Rule of thumb for occupied spaces is that the vapor barrier goes toward the

HEATED side, in order to prevent moisture in the wall or ceiling - so in

Florida, a vapor barrier would go on the

OUTSIDE of the wall but in your area, you want it on the

INSIDE.

MOST IMPORTANT - you

NEVER want more than

ONE vapor barrier, because in the

REAL world, moisture

WILL get into the wall at times - so if you accidentally end up with something that works as a vapor barrier on

BOTH sides of a wall, that pesky moisture that makes it into the wall (one way or another) will get

TRAPPED inside and will cause rot, mold and mayhem.

By limiting actual

VAPOR barriers to

ONE side, the wall can eventually dry out inside, which is what you want.

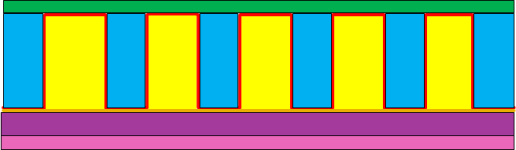

For normal house materials, even a good coat of latex paint will act as a vapor barrier, as will "trailer trash" plasticized paneling. Paper or foil as used on fiberglass batts is also a vapor barrier, especially if it's installed according to directions (overlap the backing on studs for a continual surface) - Foil on the foam insulation is the vapor barrier, so if you use that and cover the SEAMS with foil tape, that's your vapor barrier.

On the "vintage" side, tar paper on the

OUTSIDE, if overlapped like shingles but

NOT sealed, works as an

AIR barrier but allows breathing - so it would work similarly to Tyvek.

Point being, if you're aware of what DOES act as a VAPOR barrier, just make sure you only use those materials at the

INSIDE of your walls and use

BREATHABLE stuff elsewhere, such as Tyvek for an

AIR barrier on the outside.

I purposely didn't try to tell you exact materials to use, only an idea of which ones work where and why. I've seen enough of your posts to know that's probably more than you need :thumbsup: ... Steve