TX mower

Bronze Member

This not for everyone, maybe of interest if you need to replace your voltage regulator, alternator, acquire a tractor with major wiring kludges, or just like simplified electrics.

This all in the context of a 336D but some (many?) other Yanmar models are identical or very similar - up to you to determine similarities or differences and adapt as required for your specific situation. I have done this mod on my Yanmar and it works perfectly. Even if doing this on a 336D it's up to you to verify everything matches your tractor.

Background

Cost and Fitment

Instructions

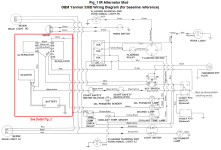

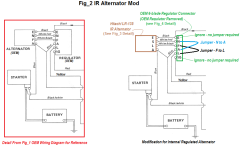

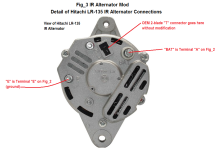

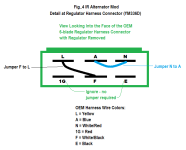

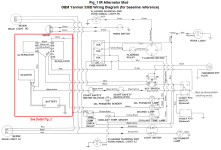

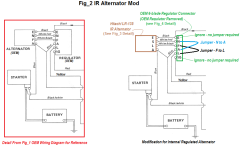

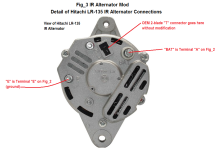

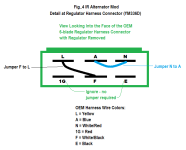

See and study the attached Figures 1 through 4 .... post-up if you've any questions.

This all in the context of a 336D but some (many?) other Yanmar models are identical or very similar - up to you to determine similarities or differences and adapt as required for your specific situation. I have done this mod on my Yanmar and it works perfectly. Even if doing this on a 336D it's up to you to verify everything matches your tractor.

Background

- The 336D shares the 35 Amp alternator and external mechanical voltage regulator found in several '60s and '70s Datsun/Nissan cars/small pickups.

- Datsun/Nissan later went to an internally regulated (IR) alternator of identical capacity, yielding simplified wiring and more reliable operation (the IR alternator uses a solid-state regulator system)

- The Datsun 1200 Club Forum has popularized and fully documented the upgrade from the older alternator+mechanical regulator system to the more modern IR Alternator system

- This post builds on that information and documents my implementation on the Yanmar 336D application

Cost and Fitment

- As of this date the price of the Hitachi LR-135 IR Alternator I used is $47.79 including the core charge but not including shipping from RockAuto (note too that 5% off codes for RockAuto are widely available via internet search)

- That price is competitive if not better than many of the Yanmar voltage regulator only replacements or alternator only replacements, while serving to replace both the alternator and the voltage regulator

- That's for a Hitachi alternator remanufactured by AC Delco and shipped in AC Delco packaging with 24-month warranty

- The alternator is complete with pulley and for me was an exact physical match bolt-on with zero modification required to any of my Yanmar mounting brackets / adjuster; the threaded adjuster-bolt hole in the alternator casting was exactly as OEM Yanmar

- See this link for the RockAuto detail page including dimensional data to verify mounting fitment for your situation RockAuto ACDELCO 3341571 = Hitachi LR-135

- In addition to the alternator, the mod requires a few inches of wire and 4 standard crimp-on male 1/4" blade connectors (to DIY two 'jumpers' installed at the OEM Yanmar 6-blade voltage regulator harness connector upon removal of the OEM regulator)

- Yes, the OEM Yanmar 336D 'charging warning lamp' will continue to function exactly as original.

Instructions

See and study the attached Figures 1 through 4 .... post-up if you've any questions.

Last edited: