I hope no one minds if I resurect this thread. I have a new irrigation problem to discuss. But first, just to pick up where it left off...

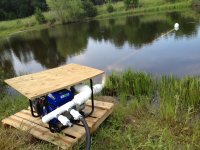

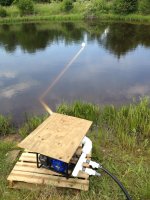

For summer of 2013 and the first part of summer 2014, I used the trash pump from the pond. We expanded our orchard to almost 40 trees and they're thriving! At the end of July 2014 we had a well put in. Simply amazing! The trash pump/pond water worked OK, but the pump I had was finicky. The trees didn't seem to mind.

Now I have a new irrigation question. On another part of our land I have a 300' row of 45 water-loving hybrid willow trees. They're doing OK, but I think they would do better if I could water them regularly. The problem is that they're approximately 2000' down the driveway from my well. Fortunately they're in a low lying area of the property and I put two 300 gallon IBC totes on the hillside above them providing abut 40 feet of head. This is then connected by 250 feet of 1/2" PE tubing to a drip system to the trees. Ideally I'd like to give each tree about 3-5 gallons per daythrough August/September. In order to fill the IBC tanks I've been using two 55 gallon plastic barrels on pallet forks on my loader. I put blukheads with 1 1/2" valves on the bottoms of the barrels to empty. A round trip fill/move/empty/return cycle with the barrels takes about 20 minutes. It works OK for what it is, but what I'd really like to do is run a dedicated water line.

So that's where my question comes in. I'm considering running 1/2" PE tubing from my closest hydrant to the IBC tanks. It's approximately 1800' distance with maybe 20' elevation change (with the hydrant being higher than the tanks). Over the span of the distance there would be a "valley" of probably 20 feet. At my well, I have 50 PSI and my well produces about 8 gpm. Even if I had to leave my water supply on 24/7, I would only need 0.06 GPM to produce all the water I need. Can someone verify with the parameters I've given that I could generate that flow? Also, could I get away with 1/4" or 3/8" (cheapter) tubing? If I get the green light on this, initially I would just lay it on the side of the driveway. After verifying that it works I would then go back and bury the tubing using my sub-soiler.

Thanks again for any advice.

BTW, for anyone that was following my Barn Build thread, I apologize for not keeping up with the posts. I haven't forgoten, I've just been busy!