Shield Arc

Super Member

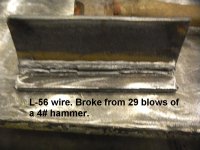

I did some fillet weld break tests a few years ago. I was shocked that Lincoln's L-56 Mig wire came out the best.

Here are the results.

6013 broke with only 3-blows of a 4-pound hammer.

6011 = 8-blows.

7014 = 10-blows.

6010 5P-Plus = 10-blows.

Tig = 13-blows.

7018 cold never seen the inside of an oven = 18-blows.

7018 right out of the oven = 23-blows.

L-56 = 29-blows.

Here are the results.

6013 broke with only 3-blows of a 4-pound hammer.

6011 = 8-blows.

7014 = 10-blows.

6010 5P-Plus = 10-blows.

Tig = 13-blows.

7018 cold never seen the inside of an oven = 18-blows.

7018 right out of the oven = 23-blows.

L-56 = 29-blows.