First of all, thanks for all your comments, I (always) find them very useful !

I decided to give it a go and went to the local welding supplier and took several

Lincoln RepTec Cast 31 2.5mm rods home. They were so friendly to sell them by the piece.

I also called several people and one gave me a link to a website who sells parts. So that was another + for today. When I got home I went on the web and found the needed pulley on their website, so I will call them tomorrow for a price on the pulley.

I was planning to prep the crack tomorrow and give it a go, but reading through your answers set me a step back and got me thinking. There is one answer in particular that gave me a whole other look at the vendor's "story" on how this pulley was damaged this way.

Looks like there has already been a fair amount of pounding on the shaft, and that dent tells me a puller is likely what broke the pulley. I'm thinking you need to get that hot to get the hub to expand and break the rust free, probably grind the mashed over rod some too. This also tells me you need to get the hub off to track down whatever that other issue is

GLyford: I think you hit it right on the spot !!

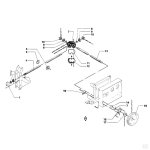

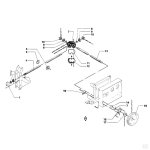

If you look at the picture the marked area should be backwards, but it is not possible to get it that way back on, so the pully has broken of to the front with a snap.

On this website there is also a scheme of how it is assembled. In a normal situation the pulley should slide off once the linchpins are removed, but there are no more linchpins present and it stil is stuck like ****.

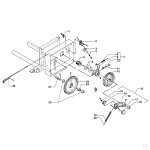

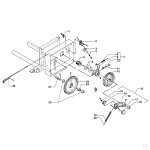

So my first task will be grinding the shaft until I can slide the base of the pulley off, maybe put some heat on it. That way it will be a lot easier to weld too. In the meantime I can inspect the rest of the shaft. I noticed there is tolerance on the big gear wheel so maybe they wanted to change the bushing of it ... anyway we will never know. I can turn the pto shaft by hand and everything seems to spin so I think the base will be okay, and maybe I just need to replace some bearings. The main shaft are ball bearings, same for the breaker shaft, the big gear wheel has a bushing.

The rod specs say:

Residual stresses are decreased by peening after each layer

http://www.lincolnelectric.com/asse...odes-RepTec-RepTecCast31/REPTECCAST31-eng.pdf

I suppose hitting it with a hammer will do fine but opinions seem to differ. What are you thoughts on this peening matter ? I have no tools for it so I will have to do it manually.

Thanks