The older John Deere tractors usually have a screen towards the bottom left hand side of the tractor behind the hydraulic filter. Drain the hydraulic fluid and pull the screen out to see if it is full of debris. Also, if you don't use the right hydraulic fluid for John Deere, it can cause the problem you described from the clutch and brake linings (from what I have read).

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

JD 301 hydraulics are dead!

- Thread starter jeep67

- Start date

- Views: 27204

More options

Who Replied?

/ JD 301 hydraulics are dead!

#21

This is what I did today:

1) Drained the oil and pulled the pre-filter. The filter was partially clogged with, can you believe it, leaves, pine needles, and some chucks of blue atv sealant. Overall, I would say the filter may have reduced flows by about 30%. I cleaned and replaced the filter.

2) Removed the pressure control valve (Priority valve?) located rear of the filter bowl. When I took the valve apart I noticed a couple interesting things, the plunger thingy inside the piston was jammed sidways and there were five washers instead of two....bingo, the problem! Or at least I thought so at the time. Let me explain, the plunger thingy resides inside the piston that slides inside the housing of the pressure control valve. Behind it is the washers, which I assume someone before me placed there as shims, followed by a spring. I assume that this valve is open when the pressure from the closed-center pump is high (i.e. about 2200 psi) and closed when the pressure is low. When open, flow is directed to the brakes, the power steering, the loader, and the 3-point hitch and when closed, the flow is directed only to the brakes and the power steering. Against my better judgment I replaced the pressure control valve on the tractor with the plunger thingy and washers back in place.

3) Next I refilled the tractor with hydraulic oil (the oil is a hygaurd variety that is correct for this application), crossed my fingers, and fired up the tractor hoping that everything would return to normal (or at least to pre-problem condition). However, it wasn't ment to be. The dang thing is still not working. The loader and the 3-point hitch don't work and the power steering just barely works.

4) Thinking the CC pump is shot I disconnected the pump shaft from the front of the engine and rotated it by hand to see how "it felt". It rotated freely but with some resistance as the pump stroked.

I still don't know if the OC pump, the CC pump, or both are broken.

So now my next plan is to get a new pressure control valve (internals only), disconnect and cap off the hydraulic line going to the power steering pump to make sure that it isn't the problem causing a loss in pressure, and get my hands on a pressure meter so I can check the status of the two pumps. Let me know if this is the correct approach.

1) Drained the oil and pulled the pre-filter. The filter was partially clogged with, can you believe it, leaves, pine needles, and some chucks of blue atv sealant. Overall, I would say the filter may have reduced flows by about 30%. I cleaned and replaced the filter.

2) Removed the pressure control valve (Priority valve?) located rear of the filter bowl. When I took the valve apart I noticed a couple interesting things, the plunger thingy inside the piston was jammed sidways and there were five washers instead of two....bingo, the problem! Or at least I thought so at the time. Let me explain, the plunger thingy resides inside the piston that slides inside the housing of the pressure control valve. Behind it is the washers, which I assume someone before me placed there as shims, followed by a spring. I assume that this valve is open when the pressure from the closed-center pump is high (i.e. about 2200 psi) and closed when the pressure is low. When open, flow is directed to the brakes, the power steering, the loader, and the 3-point hitch and when closed, the flow is directed only to the brakes and the power steering. Against my better judgment I replaced the pressure control valve on the tractor with the plunger thingy and washers back in place.

3) Next I refilled the tractor with hydraulic oil (the oil is a hygaurd variety that is correct for this application), crossed my fingers, and fired up the tractor hoping that everything would return to normal (or at least to pre-problem condition). However, it wasn't ment to be. The dang thing is still not working. The loader and the 3-point hitch don't work and the power steering just barely works.

4) Thinking the CC pump is shot I disconnected the pump shaft from the front of the engine and rotated it by hand to see how "it felt". It rotated freely but with some resistance as the pump stroked.

I still don't know if the OC pump, the CC pump, or both are broken.

So now my next plan is to get a new pressure control valve (internals only), disconnect and cap off the hydraulic line going to the power steering pump to make sure that it isn't the problem causing a loss in pressure, and get my hands on a pressure meter so I can check the status of the two pumps. Let me know if this is the correct approach.

I wouldn't just start replacing parts. I would get a John Deere service manual and check the pressure at the different test ports to isolate the problem. It will tell you what the pressure should read at different locations and at various RPM's. The 301 industrial is similar to the John Deere 1020 farm version.

dcyrilc

Super Member

I just found this thread today. I have a 2240 which is nearly identical to your 301. As I read the posts, the first thought which came to mind was the sump screen being clogged.

Your steering and priority valves shouldn't be your problem. I just finished completely rebuilding my power steering and can tell you that if you had a leak internally in the steering to cause this, 1) it would happen 100% of the time not just after it warmed up, and 2) you definately would know by the amount of heat generated in the steering colulmn. I had blown O-rings and didn't loose enough pressure to defeat the loader.

As for the priority valve, it is pressure sensitive only allowing fluid to the loader and 3PH if the system pressure is great enough. It ensures fluid to the steering and brakes if pressure is low by denying it to the loader and 3PH. Not saying it can't be bad, just that it won't cause the symptoms you have.

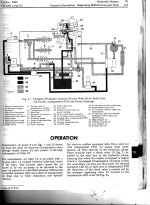

Here are a couple of scans from the tech manual for the hydraulic system basic operation. They should help you to understand the basic operation. I would highly suggest contacting John Deere and getting a tech manual. Then testing pressure from the internal pump. My suspission is that it is an internal problem. Another quick check, is to remove the cap for filling the hydraulic fluid and look for mist in the resivoir while tractor is running. There are lines in the resivoir which are known to crack and blow fluid inside the resivoir causing pressure loss.

Your steering and priority valves shouldn't be your problem. I just finished completely rebuilding my power steering and can tell you that if you had a leak internally in the steering to cause this, 1) it would happen 100% of the time not just after it warmed up, and 2) you definately would know by the amount of heat generated in the steering colulmn. I had blown O-rings and didn't loose enough pressure to defeat the loader.

As for the priority valve, it is pressure sensitive only allowing fluid to the loader and 3PH if the system pressure is great enough. It ensures fluid to the steering and brakes if pressure is low by denying it to the loader and 3PH. Not saying it can't be bad, just that it won't cause the symptoms you have.

Here are a couple of scans from the tech manual for the hydraulic system basic operation. They should help you to understand the basic operation. I would highly suggest contacting John Deere and getting a tech manual. Then testing pressure from the internal pump. My suspission is that it is an internal problem. Another quick check, is to remove the cap for filling the hydraulic fluid and look for mist in the resivoir while tractor is running. There are lines in the resivoir which are known to crack and blow fluid inside the resivoir causing pressure loss.

Attachments

beenthere

Super Star Member

- Joined

- Aug 16, 2001

- Messages

- 18,616

- Location

- Southern Wisconsin, USA

- Tractor

- JD_4x2_Gator, JD_4300, JD_425, JD_455 AWS, added JD_455, JD_110, JD_X485(sold)

Anyone know if the Industrial Deere 400 (cir 1975) has similar hydraulics to this 301?

sawmant

New member

I have a 400 Industrial Loader with FEL and TPH with same problem. Fired it up on a cold morning and loader and TPH worked for a couple of minutes then all hydralics quit. I installed to rebuilt pump last fall to replace a bad leaker and the system performed well until last week. This tractor pump has an electric solonoid on it. The fluid is cloudy white if that means anything. Any ideas other than those listed above?

dcyrilc

Super Member

I have a 400 Industrial Loader with FEL and TPH with same problem. Fired it up on a cold morning and loader and TPH worked for a couple of minutes then all hydralics quit. I installed to rebuilt pump last fall to replace a bad leaker and the system performed well until last week. This tractor pump has an electric solonoid on it. The fluid is cloudy white if that means anything. Any ideas other than those listed above?

Milky white color usually indicates water in the hydraulic fluid. Water can freeze shutting down your hydraulics.

Sawmant, I have a 400 and have not used in winter time cause it will break the bolt in the filter that returns from loader and or backhoe.( I guess I have not even started it in 2 years hope nothing is stuck!) I left mine sit out side and moisture will find its way through shifter boots and where ever. Mine woud freeze in there in away that there was no relief.

Beenthere, the 400 from what I seen on this post it is very similar except maybe the older 400 had a little different arangements on power steering. The later models of the 400 are much the same.

I am not going to say a heck of alot on this but there is 2 guys on this post that sounds like if you would try contacting them they have very good knowledge on this system.

Beenthere, the 400 from what I seen on this post it is very similar except maybe the older 400 had a little different arangements on power steering. The later models of the 400 are much the same.

I am not going to say a heck of alot on this but there is 2 guys on this post that sounds like if you would try contacting them they have very good knowledge on this system.