Hysyde

Gold Member

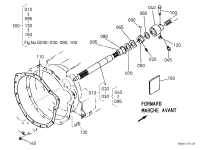

While mowing with my old Kubota F2100 front mount mower the other day I came to a abrupt halt accompanied by a grinding noise. It didn't take long to figure out that the coupler coming from the engine/clutch was spinning on the input shaft for the HST.

Replacing the through bolt only got me so far (I snapped 3 to finish the yard) and I switched to a grade 10.9 (up from 8.8) which only got me so far as well.

I realize I brought this on myself as I use the tractor to pull heavy loads of wood out of the bush, and will often rock it back and forth when getting stuck in snow/mud ruts. Not what this tractor was designed for, but it's been a tough machine, taking this abuse for years.

I wondering what my options might be at this point. A look on the Kubota parts finder page puts this shaft at nearly $1200 which is a lot of money to invest in this old girl (about 3500hrs on the meter). Pluis this isn't a job I see doing myself. Pulling the HST doesn't look too bad, but I don't intent on splitting the case myself.

Could I have the shaft built up with weld and new splines machined?

What about welding the coupler right to the shaft, since it's ruined anyway?

Also, what is the purpose of the grease fitting for a coupler that doesn't move on account of the through bolt?

Any recommendations are appreciated.

Replacing the through bolt only got me so far (I snapped 3 to finish the yard) and I switched to a grade 10.9 (up from 8.8) which only got me so far as well.

I realize I brought this on myself as I use the tractor to pull heavy loads of wood out of the bush, and will often rock it back and forth when getting stuck in snow/mud ruts. Not what this tractor was designed for, but it's been a tough machine, taking this abuse for years.

I wondering what my options might be at this point. A look on the Kubota parts finder page puts this shaft at nearly $1200 which is a lot of money to invest in this old girl (about 3500hrs on the meter). Pluis this isn't a job I see doing myself. Pulling the HST doesn't look too bad, but I don't intent on splitting the case myself.

Could I have the shaft built up with weld and new splines machined?

What about welding the coupler right to the shaft, since it's ruined anyway?

Also, what is the purpose of the grease fitting for a coupler that doesn't move on account of the through bolt?

Any recommendations are appreciated.