I've been really busy during the last week of June and the first week of July and have not updated this thread. Shortly after posting the previous note about not getting my parts, I emailed my JD dealer to ask if I could pick up the parts he had in stock since I was going to be by the dealership. The parts guy responded that he had not seen my order at all, but with the info I gave him, he found the order online in their system and he had all the parts available. I stopped in the next day and picked them up. What a surprise!

The parts total came to $9 less than what I was quoted online. It wasn't shipping because that would have been added to the online price. I was really amused by all this because not many people talk about John Deere and cheaper in the same sentence.

They even put all my parts into a nice heavy-duty John Deere paper bag. Woohoo!:thumbsup:

Only earlier this week did I get around to installing the PTO clutch retainer strap and repairing the electrical wiring where it was jerked out of the harness when the clutch spun. It was an easy job to accomplish using crimp-on splices. I carefully located the harness out of harms way and tied it up with cable ties.

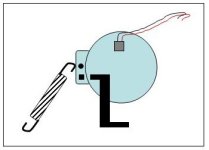

In addition to replacing the clutch retainer strap, I added a spring as a backup in case the strap ever breaks again from metal fatigue. I'm not really happy with the strength of the strap (illustrated by the Z-shaped black object in the illustration below. The clutch (shown in light blue) has a hole where one leg of the strap goes and the other leg bolts to the frame. I notice that in addition to the hole for the strap, there was a round hole available on the clutch. I had a very hefty belt tensioning spring available from an old mower deck and found that I could put it into the additional hole and secure it to the frame. That way, it provides some "help" for the retainer strap and serves as a backup if the strap ever breaks. I know my paranoia is showing a bit here,

but I'm hoping the spring will provide some additional stress relief during the shock of engaging the clutch. Anyhow, it is all back together and working nicely at the moment.

One more thing... I have another thread about all the problems I've had with the B&S engine carburetor and how the float valve sticks everytime I let it sit overnight. My standard way of starting my mower has been to use compressed air to blow into the carb inlet hose to unstick the valve everytime before I started the engine. If I didn't do that, the engine would start and then die after about 20 seconds of operation due to the fuel being depleted from the float chamber. This tedious process has gone on for several months with me putting off rebuilding my carb because it was easy to remove the hose and blow air in there. Well, I found a local station with non-ethanol gasoline and bought 15 gallons for my mowers. I put one tankfull of that gasoline into my mower and like magic the sticking float valve went away. I've started the engine at least 10 times since adding the non-ethanol fuel and it works perfectly. The needle on the valve has a rubber compound on it's tip for a better seal and the ethanol must have some effect on it. I've chased this problem on and off for the last year and with one tank of fuel the problem disappeared. I think it's too dramatic to have been a coincidence. All I know is my LA145 is running perfectly again and I'm happy about that.