Thanks guys.

Gabby -- I would have 3-4 splices with the black poly. The PVC would require about 35 couplings.

When you plow in the PVC, what keeps the couplings from getting hung up on the subsoiler as it feeds through the ring/guide? I'm having trouble envisioning how that would work.

What is it that you like about the PVC that makes it easier to plow in? Is it easier to handle because you're not dealing with a big roll?

Thanks! Really appreciate all of the replies and suggestions!

MNBobcat,

I would look around more, our Menards has black poly in 100 and 250 foot rolls and some supply houses have 3-400 hundred foot rolls. The larger rolls can be a pain to man-handle, but it can be done easily with a helper. That would get you to 1-2 couplings.

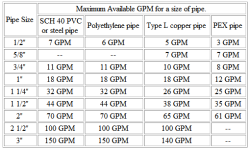

2" pipe is a lot of water and head pressure.....unless you need the maximum pipe output I'd consider maybe stepping down to 1-1/2", it's easier to handle if working with limited help. I've attached a volume chart for your reference. According to the chart (snagged on line) 2" will greatly exceed your pump capacity.

I've used black poly for years. Most problems I've seen were because of: 1) the use of the white plastic poly fittings that broke, and 2) the use of cheap hose clamps (not all stainless steel). I too have read about issues with plastic...but figure it comes with the territory. I used it 3 years ago on my house (450') ...no regrets thus far. Our local rural water company uses it for all taps from their main to their meter.

If you do use it there's a couple of things I do that make the joints really easy to get tight (and leak free

)

Install the fittings with the pipe on the soil surface. Pick up

"red brass" barbed fittings (as an example), our Menards carries a good supply of them. Use a small propane torch, heat the pipe gently around it's circumference. You know when it's "warm enough" as the pipe will look glossy, it makes slipping the fittings into the pipe (especially larger ones) in a cinch! Secure the fittings with 2 stainless steel clamps on each barbed end, pulling opposite directions and with the screws 180* opposite each other when the pipe still warm, don't over do it.

If you lay the pipe out on a "normal" sunny day and let it warm in the sun for a bit, it handles very easily. Trench the pipe below frost level, turn on the water purging the pipe of air, and to pressurize (looking for leaks) before back filling and you'll be good to go. Watch for stones; taking care to make sure you don't lay the pipe on or back fill with, large sharp rocks against the pipe.

Good luck with your decision....