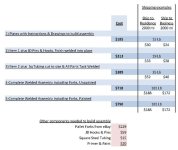

Ok folks, I finally got some numbers to share. I've spent all night working up figures, trying to keep it as low as possible. For those who will be buying just the plates and build the entire rest of the forks themselves, you'll be paying about $75

less than I did to build mine due to getting the plates made in quantity instead of just one set. Merry Christmas.

As for the rest of the configurations, there is some money figured in there for my time welding but it's not much. Truthfully, I would rather see all of you build your own so you can appreciate the work that goes into it and be proud of what you made. But for those who would rather get presents in the mail, then so be it.

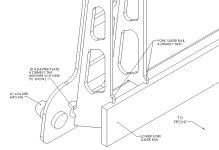

One thing to point out,

the JD pins are made of 1045 steel. This metal requires preheating, welding, then slow cooling in insulation, and finally stress relieving. Make sure you know what you are doing or you could end up with cracked welds and a useless set of pallet forks.

The price for completed assemblies are high because the forks get shipped twice. Once to me and once back to you. There isn't anything I can do about it. Sorry.

Now,

I'm taking 5% off of the cost (does not apply to shipping)

for one week to celebrate the first ones. This means any payments received before midnight 7/8/2010. No exceptions for dying grandmothers or dogs eating homework.

If you want to know what kind of person I am, you can look at my feedback on eBay under the same username, ensoll (my former company domain name, Engineering Solutions).

You can email me directly at

swissarmytractor@gmail.com but please try to keep any questions that could help others here in the forum.

I'll have to exchange payment via Paypal, checks, or cash. I'm not a big fan of Paypal but there isn't much else out there for credit card transactions. Email me for the information.

Looking forward to hearing from you,