Shield Arc

Super Member

I was ask to run a bend test over on Welding Web. I thought you guys might be interested in seeing it. After the Northridge earthquake in California Lincoln and Hobart started putting thickness limitations on their wire. Over the years I've had several welding inspectors tell me they have never seen anyone pass a bend test with NR-211. So I gave it a go this morning.

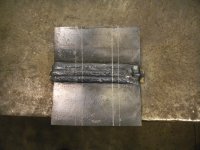

Well so much for Lincolns 1/2-inch limitation. And this was with 30-year old wire, that had a little rust on it.

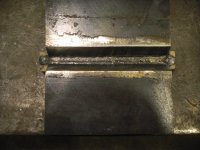

.068 NR-211 MP. Ran at 21-volts, 274-AMPS, 0.0 pinch. 3/4-inch thick plate, 35-degree bevel 3/16-inch gap, 1/4 backing plate. The little ding on the coupons is from the bender, first one I didn't place a rag under it. Second one I did, but it still got a ding.

Well so much for Lincolns 1/2-inch limitation. And this was with 30-year old wire, that had a little rust on it.

.068 NR-211 MP. Ran at 21-volts, 274-AMPS, 0.0 pinch. 3/4-inch thick plate, 35-degree bevel 3/16-inch gap, 1/4 backing plate. The little ding on the coupons is from the bender, first one I didn't place a rag under it. Second one I did, but it still got a ding.

Attachments

-

2V first slag.JPG191.8 KB · Views: 376

2V first slag.JPG191.8 KB · Views: 376 -

2V first pass.JPG238.1 KB · Views: 373

2V first pass.JPG238.1 KB · Views: 373 -

2V 4pass.JPG247.3 KB · Views: 241

2V 4pass.JPG247.3 KB · Views: 241 -

2V 8 pass.JPG241.8 KB · Views: 243

2V 8 pass.JPG241.8 KB · Views: 243 -

2V ready.JPG243.4 KB · Views: 356

2V ready.JPG243.4 KB · Views: 356 -

2V cut.JPG234.9 KB · Views: 206

2V cut.JPG234.9 KB · Views: 206 -

2V coupon1.JPG226.6 KB · Views: 217

2V coupon1.JPG226.6 KB · Views: 217 -

2V coupon2.JPG235.9 KB · Views: 192

2V coupon2.JPG235.9 KB · Views: 192 -

2V coupon3.JPG181.6 KB · Views: 228

2V coupon3.JPG181.6 KB · Views: 228 -

2V 274 AMPS.JPG236.4 KB · Views: 224

2V 274 AMPS.JPG236.4 KB · Views: 224