RDrancher

Veteran Member

The un-curl function on my TC35D started acting up yesterday and by this afternoon it was pretty much gone.

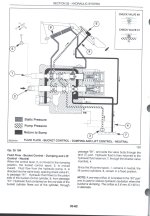

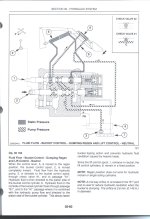

If I lay the bucket flat on the ground and try to backdrag or push, the bucket starts to curl by itself. If I stand the cutting edge straight up and down and push down on the loader arm, it doesn't have enough power to hold the position. I think that it's something in the valve, since it now has a float position past the normal un-curl position. I talked to my service tech over the phone. He believes that the bolt at the bottom of the shaft has loosened up, allowing the valve to over-travel. He said that the bolt is accessible from a plug at the bottom of the valve (spool). I don't have a diagram to refer to and couldn't find it on Messick's site. A little help please??

If I lay the bucket flat on the ground and try to backdrag or push, the bucket starts to curl by itself. If I stand the cutting edge straight up and down and push down on the loader arm, it doesn't have enough power to hold the position. I think that it's something in the valve, since it now has a float position past the normal un-curl position. I talked to my service tech over the phone. He believes that the bolt at the bottom of the shaft has loosened up, allowing the valve to over-travel. He said that the bolt is accessible from a plug at the bottom of the valve (spool). I don't have a diagram to refer to and couldn't find it on Messick's site. A little help please??

Last edited: