Well it's been a while again. First was waiting on a few replacement parts, then decided to strip and paint areas that would be difficult to get to later (behind the draft response panel, underside of the draft control housing, etc.).

With respect to the position control cam, here is a photo of the cam installed the correct way.

This was quite an easy fix with the cover off and the cams exposed. I confirmed Big Dean's statement quoted above. In fact, with the quadrants removed, you have to rotate the rod that controls the position cam outside of its normal range to get it back in place. This was very easy and it actually happened a second time after I replaced the roller but I knew what had happened and in less than a minute, had it corrected. You just have to see and feel it in the right place.

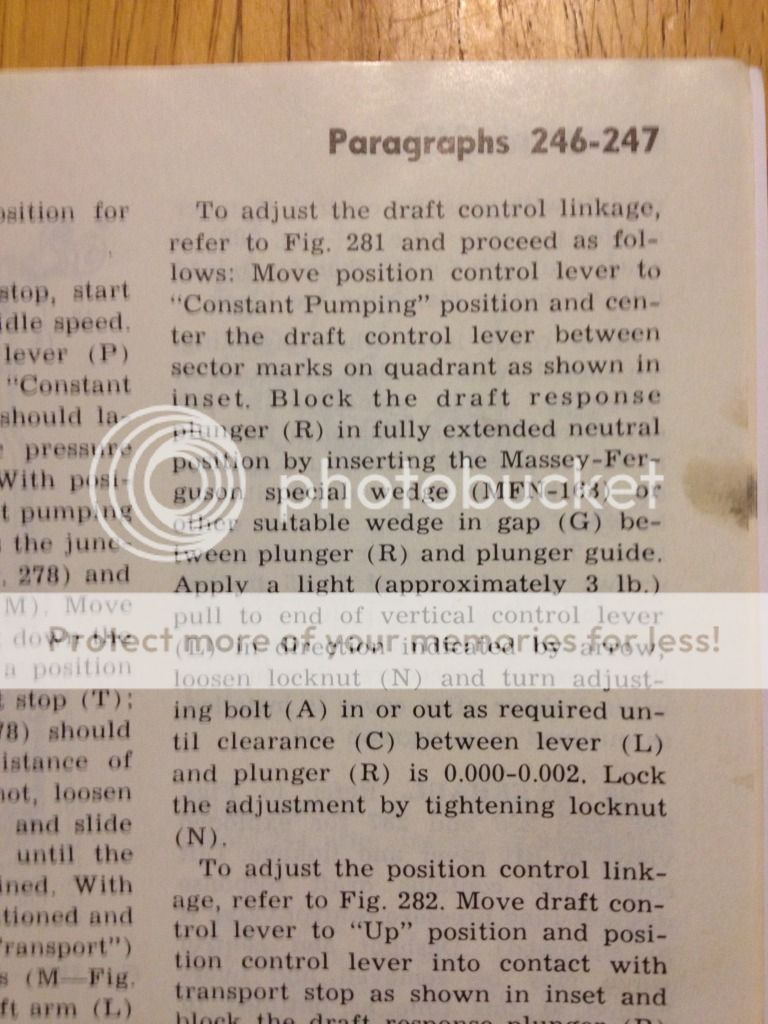

Anyway, finally got the lift cover adjusted using the I & T manual and reinstalled. Then did the final adjustments through the draft response panel. The oil tube that comes up from the pump to the lift cover was rather difficult to get installed but I believe that was due to the tight machining in the pump. Hooked up a 7' light duty blade today and dragged the driveway. Seemed to work great, hadn't used the blade before as the bushhog was hooked up when I bought it but it lifted all the way up. At least until my neighbor came by and stood on the rear of the blade. It would not lift the blade with his additional weight (approximately 200 pounds). He got off and it would lift it fine. I'm guessing it won't do well with the bushhog or a recently acquired Ford 201 flex-o-hitch disk.

I am open to any suggestions as to how to get the three point hitch to lift more weight. I contacted the dealer about adjusting the lift cover and making the final adjustments and was told it would be time and material at $85/hour. He also said it could take 2 - 6 hours. Any thoughts on this?

Thanks, Michael

With respect to the position control cam, here is a photo of the cam installed the correct way.

This was quite an easy fix with the cover off and the cams exposed. I confirmed Big Dean's statement quoted above. In fact, with the quadrants removed, you have to rotate the rod that controls the position cam outside of its normal range to get it back in place. This was very easy and it actually happened a second time after I replaced the roller but I knew what had happened and in less than a minute, had it corrected. You just have to see and feel it in the right place.

Anyway, finally got the lift cover adjusted using the I & T manual and reinstalled. Then did the final adjustments through the draft response panel. The oil tube that comes up from the pump to the lift cover was rather difficult to get installed but I believe that was due to the tight machining in the pump. Hooked up a 7' light duty blade today and dragged the driveway. Seemed to work great, hadn't used the blade before as the bushhog was hooked up when I bought it but it lifted all the way up. At least until my neighbor came by and stood on the rear of the blade. It would not lift the blade with his additional weight (approximately 200 pounds). He got off and it would lift it fine. I'm guessing it won't do well with the bushhog or a recently acquired Ford 201 flex-o-hitch disk.

I am open to any suggestions as to how to get the three point hitch to lift more weight. I contacted the dealer about adjusting the lift cover and making the final adjustments and was told it would be time and material at $85/hour. He also said it could take 2 - 6 hours. Any thoughts on this?

Thanks, Michael