Perhaps this will help. Admittedly I'm shooting out my butt on this, but it follows basic electrical theory...sort of... I know I'm going to get flayed for this, but I'll try to make some sort of layman sense out of it. No I'm not an EE, but I stayed at a Holiday Inn Express last night

1. It's a CV source, so it tries to maintain the voltage at the setting.

2. Every time you short the wire to the work as it feeds out, the voltage wants to drop as there is less resistance when it shorts than when it is holding an arc across a gap.

3. Since it tries to keep the voltage constant, it will boost the power to keep V constant.

4. Since V is held constant, A must increase and the wire melts back a bit.

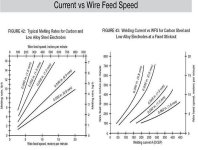

5. The faster the wire moves, the more often this must happen, thus the higher amp draw on average.

Anyone agree with me? Maybe I got that wrong, but on a Fri night, it sounds good