Great news, I got a quote back from the steel place...87.23 plus tax

Here is the cut list of steel:

QTY SIZE

5 1/2"x3"x4"

2 1/2"x3"x6"

1 1/2"x3"x8"

1 1/2"x3"x17.5"

2 1/2"x3"x24"

1 1/2"x3"x47.25"

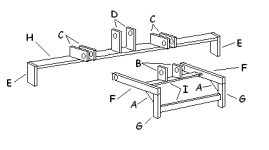

I addition, the 24" pieces would need to be cut to shape to form the jaw arms. What would it cost to have those plasma cut? Please see the attached picture for an idea of what the jaws/project looks like.

Once this is done, the fabrication will only require drilling holes and welding.

So far the cost will be $90(metal)+$10(bolts and pins)+$70(cylinder). That puts me at $170 for this phase of the project.

Next phase is figuring out the hydraulics...switch I will bring up in another thread called My First Grapple - Hydraulics

Thank you for all your help so far!

Marcus