Chuck K.

Gold Member

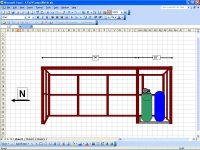

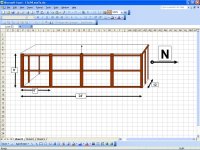

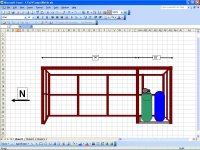

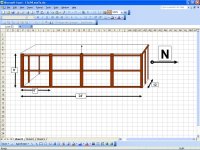

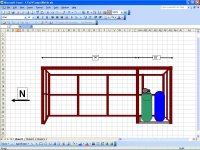

I will soon be building a 12x'x24'x9' high (at lowest eve) lean-to for storing tractor implements, riding mower, lawn tools etc.. Using treated 4x6s (~1.5 bags of sackcrete per beam) on 6 foot centers with 3 equally spaced horizontal 2x6's to attach the metal sheeting to. A 10'x12' section of the south end of the lean-to will have a 5-1/2" cement slab and will be enclosed for the air compressor and water well holding tank..

Just ordered my Leinbach PHD with a 12" auger last night after doing my home work on the forum, I am too old and out of shape to hand dig that many holes that big

I am close to the gulf coast so wind is a factor in the layout, due to my lack of building knowledge I tend to overbuild like 200' rebar in 8'x8'x3.5" slab for the wind mill) The lean-to would be sheltered for the most part from the strong south winds by the 40x60 shop.

I chose this dimension because of all the salvaged lumber I have from demo'ing a 12'x24" covered porch.

Is 4x6's on 6 centers adequate? I hope to get them ~3 in the ground. Attached is some simple drawings I did while bored at work..

Thanks for any input.. Chuck

View attachment 100809

Just ordered my Leinbach PHD with a 12" auger last night after doing my home work on the forum, I am too old and out of shape to hand dig that many holes that big

I am close to the gulf coast so wind is a factor in the layout, due to my lack of building knowledge I tend to overbuild like 200' rebar in 8'x8'x3.5" slab for the wind mill) The lean-to would be sheltered for the most part from the strong south winds by the 40x60 shop.

I chose this dimension because of all the salvaged lumber I have from demo'ing a 12'x24" covered porch.

Is 4x6's on 6 centers adequate? I hope to get them ~3 in the ground. Attached is some simple drawings I did while bored at work..

Thanks for any input.. Chuck

View attachment 100809

Last edited: