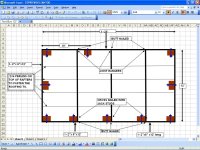

OK, for a free standing building with poles, the big question is the roof design.

You will have to use a truss of some sort to span the distance from wall to wall. It's only 12ft from each wall, so this is pretty simple. First question is how much of an overhang do you want? None? a foot?

This is the starting point for the roof trusses. Decide on that, then you will know how long to buy the 2x4's that will make up the bottom part of the truss.

Next is to figure out what pitch you want the roof to be. Is there an existing house or building close by that you want to copy the pitch? The steeper it is, the nicer it looks and the better it sheds water, but the harder it is to walk on. 4:12 is a good all around pitch. 5:12 is about the max you can walk on safely. Less of a pitch down to 1:12 will still shed water, but it will also hold leaves really bad if you have any trees close by. It's also not very attractive.

Decide on your pitch and figure two 2x6's for the top parts of the truss cut at the angle of your pitch. For a 12 foot span, you can finish off your truss with a single 2x4 that is centered on the bottom 2x4 and goes straight up to the 2x6's.

The trusses will rest on the headers at the tops of your poles. To keep is at simple as possible, you can simply bolt your boards to the tops of your posts. Two 3/8's bolts per post will do the job. With your posts on 6 foot centers, I'd use 2x8's on either side of the posts. For the ten foot span and 14 foot spans, I'd use 2x12's sandwiched together with half inch plywood between them. For this, you will have to cut off the top of the post and rest this header on top of the post. This is the maximum way to gain all the strength out of the header.

To attach the header to the tops fo the posts, I would first toe nail them in place so it doesn't fall off while working on it. You can also install temporary boards up the sides of the posts to cradle the header in position. To make it easy on yourself, you can build the header in place. That's how I do it when working alone. Just put one 2x12 in position. then tack in the plywood, and then attach the other 2x12.

When done, this will give you a level line around the top of your poles to attach your trusses.

Putting the trusses on 4 ft centers will allow you to use 2x4 purlins on the flat to attach your metal. This is what I like myself, but you can spread them out further if you want to. If you do,then you have to put the purlins on edge. The further out you go, the bigger your purlins have to be. Rule of thumb is that for 6 feet, 2x4's on edge and for 8 ft, 2x6's on edge. You can make fewer trusses, but getting those purlins secure is tougher.

I'll stop here for now. Hopefully some of the others will catch any mistakes I made or clear up areas that are confusing. LOL

Eddie