stormpetrel

Gold Member

Had some projects to do and didn't wanna pay someone to do 'em....so I bought a little Lincoln Weld-Pak and got to work. First impression? This is *not* easy My first attempts at laying down a bead were laughable.:laughing:

My first attempts at laying down a bead were laughable.:laughing:

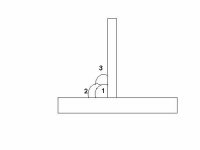

Today's project was welding a couple of grab hooks onto the top of my loader bucket. I used Lincoln Innershield 211 .035 flux core wire on the highest setting and wire feed on 3 (fairly low). Two passes did the trick. This is the first weld I've done that I though looked at all decent, and I've burned up a couple of pounds of wire practicing!

I didn't put any reinforcing plate under the hooks because the loader has a new 1/4" top (the first project I attempted) backed with 1/2" steel plate which is through-bolted to strengthen the top. I have a grapple on the bucket which bent the spit out of the top. I had reinforced the 1/8" steel w/ a piece of 1/4" angle iron which failed miserably at strengthening the top sufficiently to stop it from bending. Ahem.

backed with 1/2" steel plate which is through-bolted to strengthen the top. I have a grapple on the bucket which bent the spit out of the top. I had reinforced the 1/8" steel w/ a piece of 1/4" angle iron which failed miserably at strengthening the top sufficiently to stop it from bending. Ahem.

So I cut the entire top off, fitted a new 1/4" steel plate instead of the 1/8" that was on there originally. I lapped it over the top on the back, and butted it against the sides. I then ran a continuous bead in two passes, on BOTH top and bottom of all seams. It didn't look too pretty, but I've tested it with the largest rocks the loader/grapple can lift, and some it couldn't lift. The welds held fine, and the top of the bucket didn't re-bend.

I can't say say enough about the little Lincoln flux-core welder: it has done all I could throw at it and run perfectly. I didn't buy a bigger welder because (a) I don't have the money, (b) I don't have 220v in my garage, and (c) I wanted a new welder for my first one, and spent all I could afford trying to get a decent one (for a 110v, that is). I tried Mr. sledge on a weld I thought looked ugly (A piece of pipe welded on to a 1/4" "coupon") and my vise broke!!! So I guess ugly doesn't necessarily mean weak?

Anyhoo, I just wanted to show folks what I'm up to. And....thanks for all the good info I've collected about how to weld from "lurking" here and trying to get the right info.

The photos show the new hook, and a shot of the bucket top. Any comments, advice etc. are appreciated.

Today's project was welding a couple of grab hooks onto the top of my loader bucket. I used Lincoln Innershield 211 .035 flux core wire on the highest setting and wire feed on 3 (fairly low). Two passes did the trick. This is the first weld I've done that I though looked at all decent, and I've burned up a couple of pounds of wire practicing!

I didn't put any reinforcing plate under the hooks because the loader has a new 1/4" top (the first project I attempted)

So I cut the entire top off, fitted a new 1/4" steel plate instead of the 1/8" that was on there originally. I lapped it over the top on the back, and butted it against the sides. I then ran a continuous bead in two passes, on BOTH top and bottom of all seams. It didn't look too pretty, but I've tested it with the largest rocks the loader/grapple can lift, and some it couldn't lift. The welds held fine, and the top of the bucket didn't re-bend.

I can't say say enough about the little Lincoln flux-core welder: it has done all I could throw at it and run perfectly. I didn't buy a bigger welder because (a) I don't have the money, (b) I don't have 220v in my garage, and (c) I wanted a new welder for my first one, and spent all I could afford trying to get a decent one (for a 110v, that is). I tried Mr. sledge on a weld I thought looked ugly (A piece of pipe welded on to a 1/4" "coupon") and my vise broke!!! So I guess ugly doesn't necessarily mean weak?

Anyhoo, I just wanted to show folks what I'm up to. And....thanks for all the good info I've collected about how to weld from "lurking" here and trying to get the right info.

The photos show the new hook, and a shot of the bucket top. Any comments, advice etc. are appreciated.