defranks

Silver Member

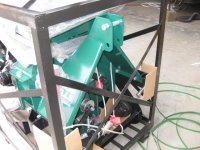

This morning I ordered a new WC68 wood chipper from Woodland Mills. I looked at several similarly priced models, including the 8" version available on eBay for a little less money, but finally decided that the WM model is right for me.

The eBay model, out of California, has its hydraulic hoses dangling on the side, and that worried me since I'll be dragging limbs past it. The WC68 has a lighter flywheel than the competitor's model, but I like that the input chute folds for storage and the reviews are good. Also, the chipper is in-stock and delivery should occur in a week or ten days.

I figured that the 6" model is plenty for me, and the best match for my Branson 4220 tractor, which is rated at 36 PTO horsepower. According to the WM website, my tractor will drive their 8" chipper, but they say that my tractor will handle 6" material with the WC68, but only 5" material with the bigger chipper. I intend to use it on smaller stuff than that, as I have neighbors who will want anything much bigger than 4" for firewood.

More to come when the chipper gets here as I assemble it and test it.

One question for the group: Woodland Mills suggests ISO 32 Hydraulic Oil, or ISO 46 in warmer climates. I live in eastern Tennessee where it certainly gets warm in the summer and cold (like today) in the winter. So which weight oil is better for a wide variety of temperatures ranging from 30, say, to 85 degrees F. Outside those temps I'm unlikely to want to be chipping wood outdoors anyway!

The eBay model, out of California, has its hydraulic hoses dangling on the side, and that worried me since I'll be dragging limbs past it. The WC68 has a lighter flywheel than the competitor's model, but I like that the input chute folds for storage and the reviews are good. Also, the chipper is in-stock and delivery should occur in a week or ten days.

I figured that the 6" model is plenty for me, and the best match for my Branson 4220 tractor, which is rated at 36 PTO horsepower. According to the WM website, my tractor will drive their 8" chipper, but they say that my tractor will handle 6" material with the WC68, but only 5" material with the bigger chipper. I intend to use it on smaller stuff than that, as I have neighbors who will want anything much bigger than 4" for firewood.

More to come when the chipper gets here as I assemble it and test it.

One question for the group: Woodland Mills suggests ISO 32 Hydraulic Oil, or ISO 46 in warmer climates. I live in eastern Tennessee where it certainly gets warm in the summer and cold (like today) in the winter. So which weight oil is better for a wide variety of temperatures ranging from 30, say, to 85 degrees F. Outside those temps I'm unlikely to want to be chipping wood outdoors anyway!