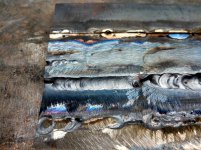

Arc weld

Veteran Member

Try working with a 2nd year apprentice who already knows-it-all. :mur: I was supposed to be a shop supervisor(a long story) at a place that had kind of a secondary shop to the side of the main shop. They built box shaped incinerators from 1/4" plate about 5' square and lined them with refractory cement. The guy acting as lead hand for these was a 2nd year and too full of himself to listen how to make a proper corner joint. He was putting one plate inside the other and welding the inside and outside of the corners. In his mind it was stronger this way. He took real offence when I suggested fitting inside corner to inside corner to leave a perfect joint for a full strength fillet weld from the outside!:talktothehand: Anywhere else they would have told him to shut and listen or hit the road. I heard after the fact that the guy didn't like working with me. What's even sadder is the foreman before me didn't have a clue either. It boggles the mind sometimes how some people in the trade don't even know the most basic stuff.