I've been very busy with work lately and haven't had a chance to work on the generator project. But today I had some time and I went and bought an old International Scout transmission. I think this will be my new speed increasing gearbox.

I look at the Facebook marketplace almost every night before bed and I've watched this guy drop the price several times now. When it got below $200 I got interested and started researching it.

It's a T90AA, of which Google doesn't seem to know much about. Apparently it's less common than the T90A and the T90C. The T90C has a 1st gear with a 3.34:1 ratio which is exactly what I need, and the output shaft is a 1-3/8" 6-spline, same as my tractor's PTO. Seems like a perfect fit. But this isn't a T90C. I wanted to go look at it and see what spline it has and what the ratios are. I couldn't do either; I couldnt see the output spline because there was a transfer case on it, and I couldn't resolve the gear ratio because i couldn't rotate the input/output as it was locked up.

They guy just wanted it out of his garage and I think I was the first person to come look at it. I lost interest when I found it was locked up but he said he would give it to me for $75 so I bit. I figured I could sell the transfer case alone for that much.

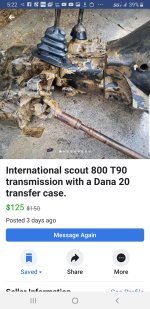

Got it home and immediately found why it was locked up. The forks were disengaged from the sliding gears and they were sitting in invalid positions. Also everything that wasn't submerged in oil was rusty.

Well i took it totally apart and gave it a good bath in the parts washer and put it back together. It works just fine and actually looks excellent inside apart from the rust pits it has.

Unfortunately it does not have the 3.34:1 first gear that I was hoping for. It's a 2.79:1 first gear but it does have the 1-3/8" 6-spline output and tractor couplers fit perfectly on it. In fact the extender pictured has a perfect OD to match the oil seal on the output.

While it doesn't have the 1st gear that I was hoping for, it does have a 3.79:1 ratio in the reverse gear which will allow me to hit 1800 generator RPM at 475 PTO RPM. It could be good or bad, I'm not sure. I think it will burn less diesel but will be limited in output power.

At the last minute the guy remembered he has the flywheel and clutch for it (but not the clutch plate) so I'm thinking I might try to find a clutch plate and use thing's own clutch to get it started. Machining a flywheel adapter would be easier than broaching an internal spline adapter anyways. And then I don't need to worry about getting a PTO slip clutch.