JB4310

Super Member

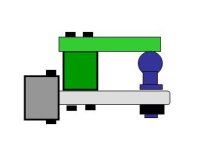

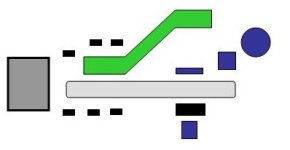

Take the ball off and drill a hole in the top of the green hammer-strap thing then just drop a pin down from the top, you'd have a clevis draw bar perfect for that pintle ring. fast and easy to couple/uncouple compared to unbolting.

There was just a thread recently about the clevis option for draw bar and I thought about your application. see reply #7 and #14.

http://www.tractorbynet.com/forums/new-holland-owning-operating/139835-clevis-question-2.html?

As far as FWJ's idea with the swinging hammer-strap, it wouldn't require the pin to be anything special, just would want the hammer-strap to extend rearward of the back retaining bolt a little further than it shows in Jinman's pic, the front hole would have the pin and just prevent the strap from moving side to side. basically a home made pintle/ball combo.

JB.

There was just a thread recently about the clevis option for draw bar and I thought about your application. see reply #7 and #14.

http://www.tractorbynet.com/forums/new-holland-owning-operating/139835-clevis-question-2.html?

As far as FWJ's idea with the swinging hammer-strap, it wouldn't require the pin to be anything special, just would want the hammer-strap to extend rearward of the back retaining bolt a little further than it shows in Jinman's pic, the front hole would have the pin and just prevent the strap from moving side to side. basically a home made pintle/ball combo.

JB.

Last edited: