Mosey

Veteran Member

- Joined

- Jan 4, 2002

- Messages

- 1,565

- Location

- Conifer, Colorado

- Tractor

- 2000 New Holland TC29D with 7308 FEL, and top & tilt. 1950 John Deere B. 1940 Farmall A.

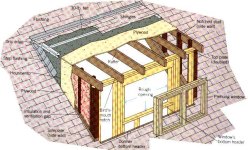

You folks have been a great help on my pole barn/garage planning. I still need to go buy a book or two and maybe even buy some plans that will be close to what I need and modify them slightly to get exactly what I want. I called a local place that sells car lifts and found out I don't want an in ground one after all, they're way too expensive, expensive to install, and expensive to repair. They have to go over 10 feet deep! So, I'm figuring on an above ground one that would be about $2500 including tax and installation. It doesn't require a 14' ceiling, the poles on each side are 12' 5" high, so the poles can just go between two roof trusses if I build a 12' tall building. The reason the poles on the lift go that high is so they can put a cross brace between them to make it stronger, and the cross brace needs to be up high enough to be out of the way of the top of the vehicle being lifted. So, the bottom of the cross brace is 12' high, which is enough to lift a full size pickup over 6' off the ground without the top hitting. I'm not planning on getting the lift right away, I just want to plan for it so I can put one in someday.

So, I'll be building a 12' tall building instead of a 14' one, which will be easier and cheaper. I had already gone to 84 Lumber on Saturday and got a price on a 14’ high one with a shingled roof and vinyl siding, and it's under $2500 delivered (without doors). That was with 6x6 poles spaced 6’ apart. The guy at 84 Lumber was very helpful and drew up a design for me right on the spot. I’ll have to check to see if a 12’ high one can use 4x4 poles.

I’m going to build it where I had fill dirt hauled in early last year (if interested, see <A target="_blank" HREF=http://www.tractorbynet.com/cgi-bin/compact/showflat.pl?Cat=&Board=rural&Number=42617&page=&view=&sb=&o=&vc=1>fill dirt and surface preparation</A>). I have it built up to the same level as a concrete pad next to the house, which required about 20 dump truck loads of fill dirt. I’m going to see what it will take to get enough fill dirt on the edges of the site to build it 24’ wide instead of 22’, since 24’ roof trusses are a standard size and much cheaper than custom built 22’ ones, plus the extra 2’ of room will be handy. I need to grade it down to allow for a couple of inches of gravel and the concrete anyway, so I might be able to grade it down and push the extra dirt to the edges to make it enough wider for a 24’ wide building. It’s packed down pretty good now, so I’ll probably need to go over it with the tiller first. My neighbor has a 6’ box blade that I can borrow, which will probably come handy.

That’s the plan anyway!

So, I'll be building a 12' tall building instead of a 14' one, which will be easier and cheaper. I had already gone to 84 Lumber on Saturday and got a price on a 14’ high one with a shingled roof and vinyl siding, and it's under $2500 delivered (without doors). That was with 6x6 poles spaced 6’ apart. The guy at 84 Lumber was very helpful and drew up a design for me right on the spot. I’ll have to check to see if a 12’ high one can use 4x4 poles.

I’m going to build it where I had fill dirt hauled in early last year (if interested, see <A target="_blank" HREF=http://www.tractorbynet.com/cgi-bin/compact/showflat.pl?Cat=&Board=rural&Number=42617&page=&view=&sb=&o=&vc=1>fill dirt and surface preparation</A>). I have it built up to the same level as a concrete pad next to the house, which required about 20 dump truck loads of fill dirt. I’m going to see what it will take to get enough fill dirt on the edges of the site to build it 24’ wide instead of 22’, since 24’ roof trusses are a standard size and much cheaper than custom built 22’ ones, plus the extra 2’ of room will be handy. I need to grade it down to allow for a couple of inches of gravel and the concrete anyway, so I might be able to grade it down and push the extra dirt to the edges to make it enough wider for a 24’ wide building. It’s packed down pretty good now, so I’ll probably need to go over it with the tiller first. My neighbor has a 6’ box blade that I can borrow, which will probably come handy.

That’s the plan anyway!